Got the motor and controller in a couple days ago and made some good headway in the interim.

They're nice enough, although I didn't expect neither the motor nor the controller to be as big as they are. The controller box is much larger than it looked on the A-Zon ad and the motor, while only 550W is significantly larger then the Customcrafter motors I have on my lathe and mill. Not a dealbreaker and the motor in this sixe is almost a direct fit to replace the factory motor, so that at least eliminates some work.

Motor, controller and 18T pully W 15mm bore from A-Zon that will work perfectly without modification.

What did need modification was the length of the motor shaft to get the drive pully in line with the driven pully.

In this pic you can see the 1/8" aluminum plate, shaft extension coupler and the locking screw for the extension. The aluminum plate is necessary as in the above pic you can see that the front of the motor is stepped and the plate will allow me to mount it flat without a lot of hassle. Just need to drill two holes for the mounting bolts.

In making parts for something I don't have with me at the time, I just make them "Long enuf" to work and trim them down at home. This is what the arraignment looks like as of now.

The pully is in its proper location and you can see how much of the extension I have extra to work with. Ill have 1/4" of room for the jam screw to engage the extension once everything is said and done. The jam screw is necessary as the rotation of the motor will unscrew the extension without some way of fixing it in place and this seemed simple enough to just cut out of a 12mm-1.75 bolt.

Now if you look closely at the above pic, just to the right of the pully you can see the end of the extension, and a slight gap between it and the motor shaft.

Yeah, about that motor shaft......

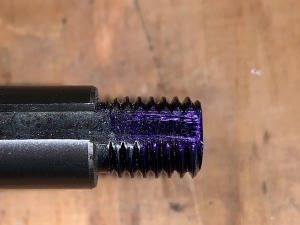

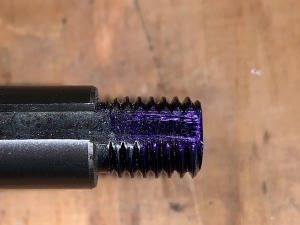

The threads on the end of this shaft are crap! They did a half assed job with the threading, either not taking a cleanup pass or not cutting deep enough, then just plowed a 5mm endmill through the threads and called it good.

I was a bit concerned when my extension wouldn't thread on, so I blued up the threads and got out the needle file and began cleaning them up wherever the bluing showed interference. This pic is after the third iteration of bluing and

cursing....I mean fitting.

This yielded me little if any headway and I was getting a bit miffed at this, until I remembered the nut supplied with the motor wouldn't thread on either. You can see in the above pic how flat the thread tips are which clued me in to them not being cut deep enough. Through some poking around at work I found a tap that must have been made in the same prefecture as this motor, as it had a really crappy looking thread profile, ran that through the extension and VIOLA! The extension just barely threads on. I'm actually OK with this as the way things are the extension runs true and will only get better once the two shoulders meet.

Except, remember that gap? Yeah, there's no undercut in the thread runout/gutter.

Ill deal with that next and then mount the motor.