-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting dovetails-Machinery's Handbook and video

- Thread starter Janderso

- Start date

- Joined

- Mar 26, 2018

- Messages

- 8,413

Yes, one for each jaw.To make this work, do you need two tee-nuts for each clamp? One for each jaw?

- Joined

- Mar 26, 2018

- Messages

- 8,413

You are the creative one Mr. WhoopI'm thinking this could be modified with a single screw and tee nut with a large "washer" that pushes down the movable jaw as the screw is tightened. Just thinking out loud.

- Joined

- Mar 26, 2018

- Messages

- 8,413

I’m struggling with the way to determine how wide to cut the male side before I cut the dovetail.

I understand the pins would measure across the point where they touch at the taper of each side of the dovetail.

If I cut to that measurement it will be too narrow. At least the way my mind works. I plan on cutting the female first.

There are several very detailed videos on the trig involved but I am hoping to avoid that method. It causes steam to come out of my ears!

I understand the pins would measure across the point where they touch at the taper of each side of the dovetail.

If I cut to that measurement it will be too narrow. At least the way my mind works. I plan on cutting the female first.

There are several very detailed videos on the trig involved but I am hoping to avoid that method. It causes steam to come out of my ears!

- Joined

- Dec 18, 2019

- Messages

- 6,538

Not that hard to derive. What do we know? We know the angle of the dovetail, and the height. What are we looking for?I’m struggling with the way to determine how wide to cut the male side before I cut the dovetail.

I understand the pins would measure across the point where they touch at the taper of each side of the dovetail.

If I cut to that measurement it will be too narrow. At least the way my mind works. I plan on cutting the female first.

There are several very detailed videos on the trig involved but I am hoping to avoid that method. It causes steam to come out of my ears!

The width of a single "half dovetail". Then the full width is 20mm + 2 * the half width, right?

a = 60 degrees.

From basic trig, we know the height y is given by, y = 4 = r * sin a. We don't know r, but it doesn't matter. Also we know that x (the width of the triangle on the right dovetail) is given by x = r * cos a.

So some simple math. r = 4mm / (sin a). This is true as long as (sin a) is not zero. Now substitute this equation into x = r *cos a, using what we determined r was. We get: x = 4/(sin a) * cos a. We can simplify if you want, but this is the distance x.

I used x = 4 * (cos a / sin a) = 4 * cot a = 4 * 1/( tan a ) = 4/( tan 60 ) = 2.3094 mm.

So x is half the distance, remember? then the full width is simply FW = 20mm * 2x = 20mm + 2*2.3094 = 24.6188 mm. Since you are probably going to chamfer the corners anyways, use something near 24.62 mm. Obviously then match the female dovetail to this, using your judgement and pins, per the handbook.

Last edited:

- Joined

- Mar 26, 2018

- Messages

- 8,413

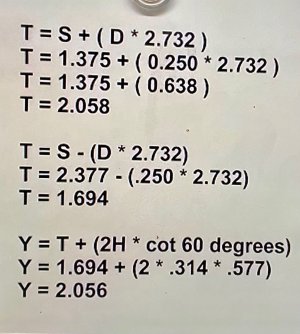

I found the formulas in the handbook.

Mr. Pete has a video, see below, along with Pragmatic Lee. They both try to simplify the math.

I'm also including or noting a simplified version using a constant, introduced by Dick Kostelnicek. See Mr. Pete's video. (about 8 minutes in)

Thanks for your help, I'll get there in the end and it really makes a difference to have all the resources provided by you guys.

The constant Mr. Kostelnicek used was 2.732

Mr. Pete has a video, see below, along with Pragmatic Lee. They both try to simplify the math.

I'm also including or noting a simplified version using a constant, introduced by Dick Kostelnicek. See Mr. Pete's video. (about 8 minutes in)

Thanks for your help, I'll get there in the end and it really makes a difference to have all the resources provided by you guys.

Volume 7, No 12 - December, 2002

Home Metal Shop Club Newsletter for December 2002

www.homemetalshopclub.org

The constant Mr. Kostelnicek used was 2.732

Attachments

Last edited:

- Joined

- Jan 20, 2018

- Messages

- 5,675

This is the way I do it. I took plenty of math and am perfectly capable of doing it, but being visual I like to see the situation. Still using the command line in Acad 2000, never cared to learn all those stupid symbols.Also if you have access to any drawing programs. Just draw what you want. Then you can derive any way you want to measure.

Cutting oil is my blood.

It comes from being lazy, I'll put a lot of thought into doing less work.You are the creative one Mr. Whoop

- Joined

- Jul 28, 2017

- Messages

- 2,399

I suspect some other folks are going to make their own versions of this. It will be interesting to see what they come up with!

One thing I like about the design is that it pushes the workpiece down as it's tightened. Sort of a mini-Kurt scheme, although the fact that the movable jaw slides down the side of the workpiece a little might be an issue for some (there's a potential for marring the edges).

A three-piece clamp with a vertical-moving wedge in the middle would address that, at the expense of a more complex and bulkier design. However, the issue is nonexistent with Hall's version so I think it wins in this regard.

One thing I like about the design is that it pushes the workpiece down as it's tightened. Sort of a mini-Kurt scheme, although the fact that the movable jaw slides down the side of the workpiece a little might be an issue for some (there's a potential for marring the edges).

A three-piece clamp with a vertical-moving wedge in the middle would address that, at the expense of a more complex and bulkier design. However, the issue is nonexistent with Hall's version so I think it wins in this regard.