- Joined

- May 1, 2011

- Messages

- 484

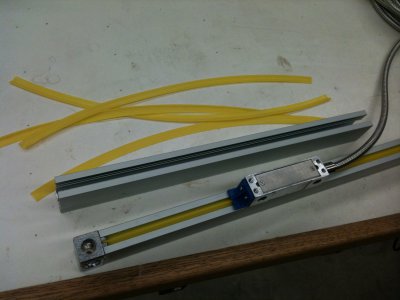

In my recent DRO thread: http://hobby-machinist.com/index.php?topic=2019.0 a comment was made stating "You cannot cut glass scales". Well, after some research I have found that indeed you can, and I did two of them today.

Here is a simple How-To on how I did it. First let me state that it is not for the faint of heart, but there where no surprises and everything that happened was predictable.

-First, I removed the endcap opposite the labels so they would remain intact, slid the reader head out, then I pulled out the 4 wipers.

-I determined that the glass was glued in (some scales it's not) and that I did not want to try removing it from the scale body, so a packed a paper towel around it to give it support during the cutting process. Then I proceeded to make a test cut, and since I had to shorten it by 15 inches I had plenty of trial and error room.

-After the test cut proved un-eventful, I cut the scale to the final length. When the blade hits the glass, it breaks in a fairly straight line, but this is NOT critical anyway since it must be trimmed back about 1/4" and the reader head is still over 2" away at it's closest point. For the trimming I just reached in and nipped at the glass with needlenose pliers since nothing else could get in there to trim the glass. Remember this is non-critical.

-Next I filed the end of the body to remove burs, Then I taped the endcap on and used a transfer punch to mark the holes for the endcap screws.

-Next I drilled the four holes-this was the most stressful part worrying about the bit breaking. The I proceeded to tap the four holes with a 2mm tap.

-After all the cutting/drilling/tapping was completed, I removed the paper towel and used compressed air to clean ant debris from inside the scale body.

-Then I slid the wipers back in and cut them with a razor blade, then re-installed the reader head.

-The last step is to apply a small bead of silicone around the endcap and install it using a dab of Loctite on the four screws.

All this took a little over 1 hour to complete, and things went so well I decided to cut down the compound slide also by 2" since it's going to be hanging of the rear (see other thread linked) I figured the less mass/length the better.

Here is a simple How-To on how I did it. First let me state that it is not for the faint of heart, but there where no surprises and everything that happened was predictable.

-First, I removed the endcap opposite the labels so they would remain intact, slid the reader head out, then I pulled out the 4 wipers.

-I determined that the glass was glued in (some scales it's not) and that I did not want to try removing it from the scale body, so a packed a paper towel around it to give it support during the cutting process. Then I proceeded to make a test cut, and since I had to shorten it by 15 inches I had plenty of trial and error room.

-After the test cut proved un-eventful, I cut the scale to the final length. When the blade hits the glass, it breaks in a fairly straight line, but this is NOT critical anyway since it must be trimmed back about 1/4" and the reader head is still over 2" away at it's closest point. For the trimming I just reached in and nipped at the glass with needlenose pliers since nothing else could get in there to trim the glass. Remember this is non-critical.

-Next I filed the end of the body to remove burs, Then I taped the endcap on and used a transfer punch to mark the holes for the endcap screws.

-Next I drilled the four holes-this was the most stressful part worrying about the bit breaking. The I proceeded to tap the four holes with a 2mm tap.

-After all the cutting/drilling/tapping was completed, I removed the paper towel and used compressed air to clean ant debris from inside the scale body.

-Then I slid the wipers back in and cut them with a razor blade, then re-installed the reader head.

-The last step is to apply a small bead of silicone around the endcap and install it using a dab of Loctite on the four screws.

All this took a little over 1 hour to complete, and things went so well I decided to cut down the compound slide also by 2" since it's going to be hanging of the rear (see other thread linked) I figured the less mass/length the better.

Last edited by a moderator: