- Joined

- Nov 25, 2015

- Messages

- 8,306

I rebuilt this a couple of years ago.

as I bought it at the sellers location.

as I bought it at the sellers location.

before cleanup and restoration

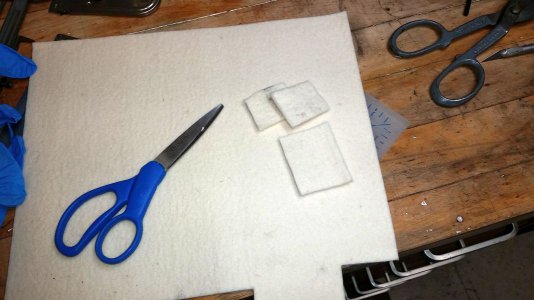

Either this paint was incredibly resistant, or the newer citristrip is not as good as the old... my opinion after doing a map cabinet this past spring was that citristrip is no longer as good as it used to be. it was incredibly difficult to remove the paint on the map cabinet. so lots of pics of small progress. I think it wound up being 6 passes of stripping.

Stripping is always a messy endeavor. I didn't strip my lathe, I used TSP and boiled the paint off in a large vat. It gave nice tooth to the lathe. And for the bed I power washed the dirt and paint off.

I milled the base flat, it was worn quite a bit. Then I did a total amateur scrape job, the goal was not flattening, the goal was oil retention. I added back missing oil grooves, that were worn away.

More to come

as I bought it at the sellers location.

as I bought it at the sellers location.

before cleanup and restoration

Either this paint was incredibly resistant, or the newer citristrip is not as good as the old... my opinion after doing a map cabinet this past spring was that citristrip is no longer as good as it used to be. it was incredibly difficult to remove the paint on the map cabinet. so lots of pics of small progress. I think it wound up being 6 passes of stripping.

Stripping is always a messy endeavor. I didn't strip my lathe, I used TSP and boiled the paint off in a large vat. It gave nice tooth to the lathe. And for the bed I power washed the dirt and paint off.

I milled the base flat, it was worn quite a bit. Then I did a total amateur scrape job, the goal was not flattening, the goal was oil retention. I added back missing oil grooves, that were worn away.

More to come

Attachments

Last edited: