- Joined

- Oct 14, 2014

- Messages

- 1,970

The recent discussion about Everede boring bars prompted this thread.

I just scored a set of Devlieg microbore bar bars for my second shop:

I have a HUGE selection of their bars for my NMTB40 mill. For decades (before huge CNC) many shops had a jig bore machine using these. They can go cheap on eBay. here's just a quick example. I did not spend time shopping for a great deal:

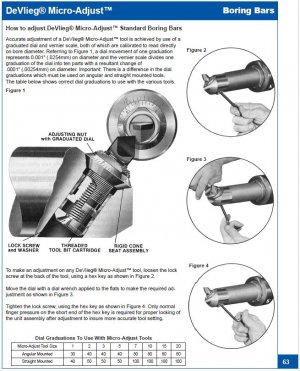

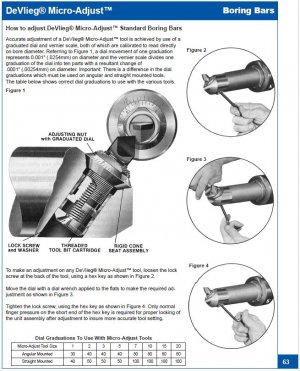

This system is FAR MORE RIGID than any other offer. The bars have replaceable grindable inserts and an accurate method to make bore adjustments, see this pic from their catalog:

I just scored a set of Devlieg microbore bar bars for my second shop:

DEVLING MICRO BORE SET SSMBS108 STRAIGHT SHANK 7/16” - 1.000" + EXTRA TIPS-USED | eBay

<p>NICE DEVLING MICRO BORE SET SSMBS106 STRAIGHT SHANK 7/16, 1/2, 5/8, 3/4, AND 1.00”. THIS SET COMES WITH WRENCHES AND EXTRA TIPS. </p><br /><p>IMPORTANT!!! —— PLEASE NOTE THIS IS NOT, REPEAT, NOT A COMPLETE SET…IT IS MISSING THE 3/8 BAR.</p><br /><p>PLEASE SEE ALL PHOTOS</p>

www.ebay.com

I have a HUGE selection of their bars for my NMTB40 mill. For decades (before huge CNC) many shops had a jig bore machine using these. They can go cheap on eBay. here's just a quick example. I did not spend time shopping for a great deal:

3 Devlieg Microbore Flash Change NMTB40 Boring Heads | eBay

<p>This set includes three DeVlieg Microbore Flash Change NMTB40 Boring Heads, perfect for workholding and toolholding in CNC, metalworking, and manufacturing industries. The brand has a reputation for high quality and these heads are no exception. They are a great addition to any workshop.</p>

www.ebay.com

This system is FAR MORE RIGID than any other offer. The bars have replaceable grindable inserts and an accurate method to make bore adjustments, see this pic from their catalog:

One of DeVlieg's specs on their jig mills was max TIR of less than .0002 on the spindle at maximum extension . We had a wall of 6 machines . Not CNC but point to point milling .

One of DeVlieg's specs on their jig mills was max TIR of less than .0002 on the spindle at maximum extension . We had a wall of 6 machines . Not CNC but point to point milling .