- Joined

- Jan 4, 2012

- Messages

- 108

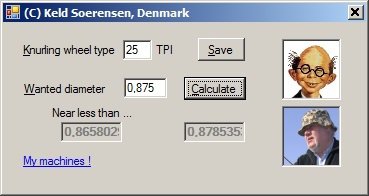

I've made a program that can do all these calculation and choose the closest diameter smaller and greather than the wanted that's "fitting" the knurling wheel !

The program markes the CLOSEST diameter blinking - some people say "Just take the smaller diameter !" - but you are free to choose - I just programmed it this way !

The program is FREE and can be downloaded from my web site ...

BUT ...

1) Your security system must allow you to install programs (EXE/MSI-files)

2) You must have Micorsoft .NET FRAMEWORK installed (download free from Microsoft)

3) Notice where you install it on your machine - you must start it from there OR make a shortcut yourself on the desktop

You can download it here:

http://kelds.weebly.com/sjov.html

Hope you enjoy it !

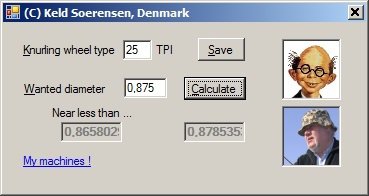

The program markes the CLOSEST diameter blinking - some people say "Just take the smaller diameter !" - but you are free to choose - I just programmed it this way !

The program is FREE and can be downloaded from my web site ...

BUT ...

1) Your security system must allow you to install programs (EXE/MSI-files)

2) You must have Micorsoft .NET FRAMEWORK installed (download free from Microsoft)

3) Notice where you install it on your machine - you must start it from there OR make a shortcut yourself on the desktop

You can download it here:

http://kelds.weebly.com/sjov.html

Hope you enjoy it !