- Joined

- Feb 21, 2022

- Messages

- 773

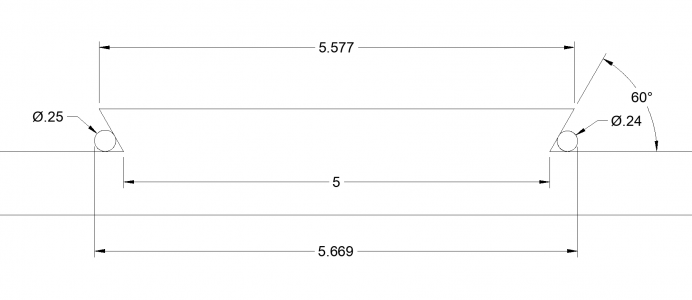

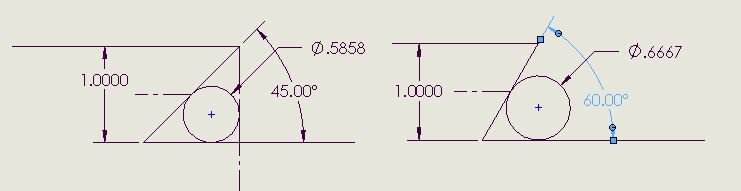

I've seen several references regarding measuring over pins to establish mating dovetails.

The common statement is to use pins of the same diameter as the depth.

**This does work on 45 degree dovetails as the angular contact point with the pin is halfway for both male and female parts. This enables the dimension over the pins in the female slot to be the same as the dimension over the pins on the male part.

However this is not the case for other angle dovetails.

If cutting a common 60 degree dovetail mating pair, a pin diameter of 1/3rd of the depth should be used.

Hope this helps anyone considering using pins of the same diameter as the depth for any angle other than 45 degrees.

**Edit: I've checked the statements regarding the 45 degree dovetais and they are also false.

The ideal pin diameter for a common dimension for 45 deree dovetails is 41% of the depth.

Sorry, I should have checked before posting, it seemed plausible, I guess that it is why that size is often quoted.

The common statement is to use pins of the same diameter as the depth.

**This does work on 45 degree dovetails as the angular contact point with the pin is halfway for both male and female parts. This enables the dimension over the pins in the female slot to be the same as the dimension over the pins on the male part.

However this is not the case for other angle dovetails.

If cutting a common 60 degree dovetail mating pair, a pin diameter of 1/3rd of the depth should be used.

Hope this helps anyone considering using pins of the same diameter as the depth for any angle other than 45 degrees.

**Edit: I've checked the statements regarding the 45 degree dovetais and they are also false.

The ideal pin diameter for a common dimension for 45 deree dovetails is 41% of the depth.

Sorry, I should have checked before posting, it seemed plausible, I guess that it is why that size is often quoted.

Last edited: