-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill Press Diagnostic?

- Thread starter A_Ninja_Racer

- Start date

- Joined

- Jul 29, 2014

- Messages

- 2,737

I had a motor with this issue...opened and looked at the centrifugal switch...it was misadjusted and would not make contact at zero RPM. Re-adjustment was trivial.

- Joined

- Nov 25, 2015

- Messages

- 8,317

just because it clicks, does not mean it's working normally. It may be that the switch is still broken.Yes you do hear it click.

Take the motor off, and remove the end bell (end cap) on the side away from the shaft, as that is usually where the cent. switch is.

take a few pics for us (clear ones from further back and from close).. then we can tell what is going on.

If the motor spins, it's probably not the bearings.. it still sounds like a capacitor issue. Whether the switch is working, OR something else.

The start winding can be bad.. or there could be a lose or disconnected wire.

- Joined

- Oct 21, 2023

- Messages

- 4

Yes it sounds like it's the start capacitor that's causing the problem.

I've got to agree with a lot of posts here-

First, if the motor spins easily by hand, the bearings might be noisy, worn, and generally need replacement (or they might be fine), but if they cause no undue resistance to turning at low speed, they are not causing a starting problem. That problem is going to lie in the capacitor, the wiring between the capacitor and the start winding, or the start winding it's self. I would start with those. As a whole, motors are a little bit intimidating if you don't fully understand them (as I certainly don't), but if you break it down to one piece at a time, it's not so bad.

Second, the circuit and the extension cord..... Yeah.... If using that cord is causing problems, that cord is a problem. Even if it "works OK", if it's so undersized that it's causing issues at startup on a working motor, then it's undersized. That means that it's causing the motors to run at a low voltage when they're running. To put it nicely, that's not good for a motor. And while you havn't offered any proof..... My spidey sense is tingling a little about the outlet you're plugging it into. I have visions of a light duty circuit, maybe backstabbed wires, being used for heavy loads. If that's going to be used for this on an ongoing basis, I'd recommend looking into that, maybe measure the voltage drop when starting or running a motor under a load, or at the very least pull the outlet out and make sure it's 12ga wire and not 14, and that it's screwed to the outlet, not backstabbed. The machines that get plugged into it will appreciate that.

First, if the motor spins easily by hand, the bearings might be noisy, worn, and generally need replacement (or they might be fine), but if they cause no undue resistance to turning at low speed, they are not causing a starting problem. That problem is going to lie in the capacitor, the wiring between the capacitor and the start winding, or the start winding it's self. I would start with those. As a whole, motors are a little bit intimidating if you don't fully understand them (as I certainly don't), but if you break it down to one piece at a time, it's not so bad.

Second, the circuit and the extension cord..... Yeah.... If using that cord is causing problems, that cord is a problem. Even if it "works OK", if it's so undersized that it's causing issues at startup on a working motor, then it's undersized. That means that it's causing the motors to run at a low voltage when they're running. To put it nicely, that's not good for a motor. And while you havn't offered any proof..... My spidey sense is tingling a little about the outlet you're plugging it into. I have visions of a light duty circuit, maybe backstabbed wires, being used for heavy loads. If that's going to be used for this on an ongoing basis, I'd recommend looking into that, maybe measure the voltage drop when starting or running a motor under a load, or at the very least pull the outlet out and make sure it's 12ga wire and not 14, and that it's screwed to the outlet, not backstabbed. The machines that get plugged into it will appreciate that.

- Joined

- Oct 17, 2023

- Messages

- 10

just because it clicks, does not mean it's working normally. It may be that the switch is still broken.

Take the motor off, and remove the end bell (end cap) on the side away from the shaft, as that is usually where the cent. switch is.

take a few pics for us (clear ones from further back and from close).. then we can tell what is going on.

If the motor spins, it's probably not the bearings.. it still sounds like a capacitor issue. Whether the switch is working, OR something else.

The start winding can be bad.. or there could be a lose or disconnected wire.

Alright I've pulled the motor off and took several pictures. Again I've already replaced the starting capacitor with a new one as of yesterday and that didn't yield any different results. Please let me know if you want me to pull the motor housing apart or if you want to see anything else.

Here is a link to a small youtube clip of the Centrifugal Switch

- Joined

- Apr 30, 2015

- Messages

- 11,328

Disconnect one cap wire, then check across those two wires of the switch with an ohmmeter or continuity tester- should be

a closed circuit with the motor at rest.

Operating the mechanism with your fingers should make the switch open

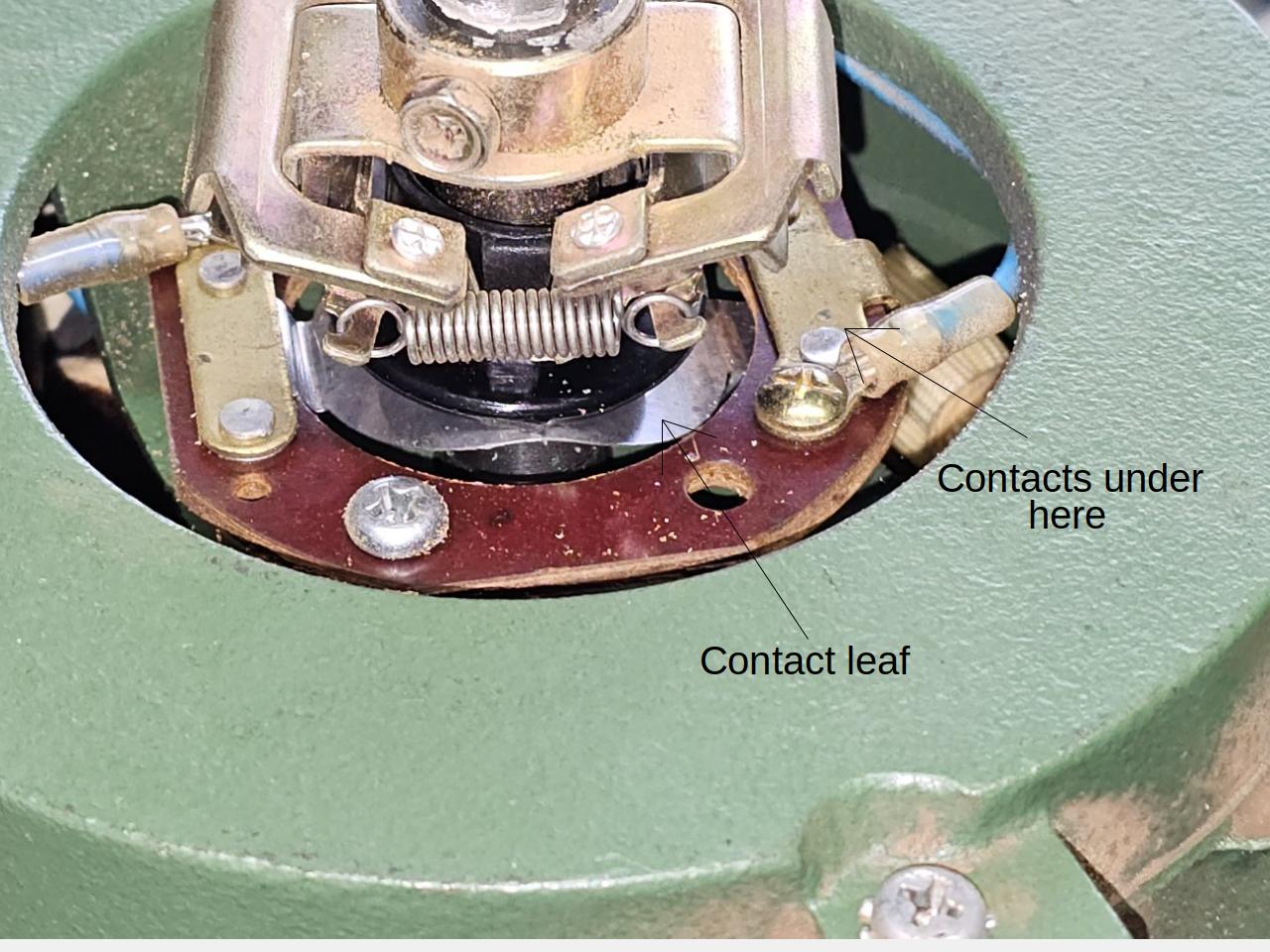

The contact leaf is shown here: It may need careful bending but be gentle with it- you don't want to break it

The weights push the black piece which pushes on the leaf to open the contacts at speed

a closed circuit with the motor at rest.

Operating the mechanism with your fingers should make the switch open

The contact leaf is shown here: It may need careful bending but be gentle with it- you don't want to break it

The weights push the black piece which pushes on the leaf to open the contacts at speed

Last edited:

- Joined

- Nov 25, 2015

- Messages

- 8,317

yep, also very hard to see what's going on, that was only the fan shroud. I would have thought that was a totally enclosed fan cooled, but it's not. its open. As Mark says. Also we need to see if there is too much pre load on the contacts. If there is, then the switch will not be closed, it will be open. when Mark says operating the mechanism, he means press in the center of the two leafs where you see the springs, the weights should go out and it should press the contact plate and move it away from the brown plate the contacts should open..Disconnect one cap wire, then check across those two wires of the switch with an ohmmeter or continuity tester- should be

a closed circuit with the motor at rest.

Operating the mechanism with your fingers should make the switch open

- Joined

- Apr 30, 2015

- Messages

- 11,328

If the switch turns out to be ok then the only thing left is an open start winding- sometimes you can locate a bad soldering joint where

the wires are spliced- locate the start winding ends by following the cap wires and the start switch wires. Check under the fabric tubing

where the splices are- you might get lucky

Otherwise you are done- new motor time

the wires are spliced- locate the start winding ends by following the cap wires and the start switch wires. Check under the fabric tubing

where the splices are- you might get lucky

Otherwise you are done- new motor time

- Joined

- Oct 17, 2023

- Messages

- 10

Hello All,

I ran a continuity test on the switch and it was closed until I manipulated the switch and then it was open. I decided to remove the switch from the motor and took a small File to the contacts because there did appear to be som corrosion or charing on the contacts I filed it down till they both had clean metal. I then reassembled the motor into the press and got pretty much the same results. I did notice one strange thing however. In the video link below I started the motor 3 times. The 1st with the belt on where the motor did not start spinning. Then 2 more times with the belt off where the motor did spin but in different directions each time. I put some sharpie marks on the pulley so that it would be easier to see. This isn't normal right? Does this symptom lead to something?

YouTube Video Clip: Drill Press Motor

I ran a continuity test on the switch and it was closed until I manipulated the switch and then it was open. I decided to remove the switch from the motor and took a small File to the contacts because there did appear to be som corrosion or charing on the contacts I filed it down till they both had clean metal. I then reassembled the motor into the press and got pretty much the same results. I did notice one strange thing however. In the video link below I started the motor 3 times. The 1st with the belt on where the motor did not start spinning. Then 2 more times with the belt off where the motor did spin but in different directions each time. I put some sharpie marks on the pulley so that it would be easier to see. This isn't normal right? Does this symptom lead to something?

YouTube Video Clip: Drill Press Motor