- Joined

- Nov 14, 2016

- Messages

- 3,262

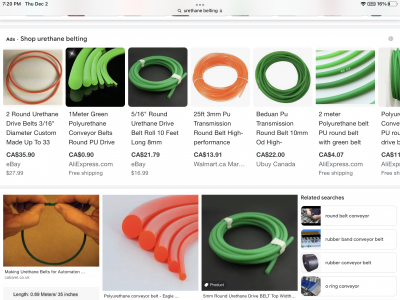

I just picked up a small watchmakers lathe, marked as Waltham Watch Tool Company. It appears to be in pretty good shape, but the thin leather belts (almost leather shoe laces) are unusable, very dry and cracked. I see a lot of people using some sort of round rubber belts on their lathes.

What are these called and where do I find some to fit my lathe?

I'll start a post for the lathe itself once I get it moved in and set up.

What are these called and where do I find some to fit my lathe?

I'll start a post for the lathe itself once I get it moved in and set up.