-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- SPECIFIC MANUFACTURERS OF MACHINE TOOLS

- BOXFORD, MYFORD, DENFORD VICEROY, EMCO & UNIMAT MACHINES

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EMCO Maximat Mentor V10

- Thread starter JWW

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

You essentially have a V10-P; the Mentor just meant it came on a stand.

The first thing I would suggest is that you take the gear train out and clean everything in there. Most problems with sticky gear movement is because of crap in the the gear bores or on the shafts. Take it apart, clean and lube everything and that may resolve your issues in the change gear area. I have no idea what that spare bushing is for but it is probably important. Not sure if it is part of the change gear set that was available for your lathe but please don't discard it.

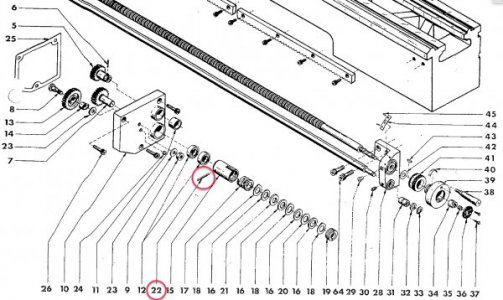

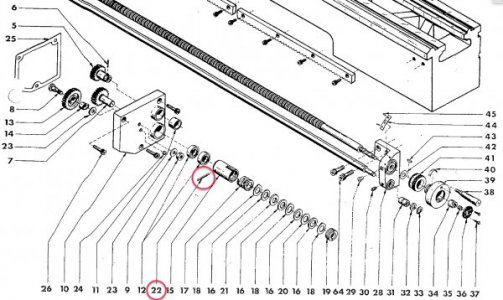

As for the non-turning feed shaft, I suspect the sacrificial shear pin is broken. That would be part 22 in the IPB that I am attaching. You have to remove the drive shaft to access it. The pin is made from aluminum and is meant to shear under excessive loads; please do not use any other material to replace it.

The leadscrew does not turn unless you are cutting threads, in which case you engage it with the threading lever on the headstock. Likewise, the gear at the bottom of the thread dial indicator at the right side of the saddle is pulled away from contact with the leadscrew until you need it for thread cutting; then you lightly engage it by rotating the indicator and locking down the screw that holds it to the saddle. When you engage the half nuts, which is the lever on the front of the saddle that you said you didn't know what it was for, that causes the saddle to move with the leadscrew to cut threads. It is normally not engaged unless you are cutting threads.

I really think you should consider tearing the lathe apart to clean and lube everything. You can do it with the parts manual below. Leave the spindle and headstock alone unless there is a problem but everything else can be taken apart and cleaned out. This will be good for the lathe and good for you because you'll learn a lot about your lathe.

I also suggest you join the Yahoo Emco Larger Lathes group. Lots of info and help there.

The first thing I would suggest is that you take the gear train out and clean everything in there. Most problems with sticky gear movement is because of crap in the the gear bores or on the shafts. Take it apart, clean and lube everything and that may resolve your issues in the change gear area. I have no idea what that spare bushing is for but it is probably important. Not sure if it is part of the change gear set that was available for your lathe but please don't discard it.

As for the non-turning feed shaft, I suspect the sacrificial shear pin is broken. That would be part 22 in the IPB that I am attaching. You have to remove the drive shaft to access it. The pin is made from aluminum and is meant to shear under excessive loads; please do not use any other material to replace it.

The leadscrew does not turn unless you are cutting threads, in which case you engage it with the threading lever on the headstock. Likewise, the gear at the bottom of the thread dial indicator at the right side of the saddle is pulled away from contact with the leadscrew until you need it for thread cutting; then you lightly engage it by rotating the indicator and locking down the screw that holds it to the saddle. When you engage the half nuts, which is the lever on the front of the saddle that you said you didn't know what it was for, that causes the saddle to move with the leadscrew to cut threads. It is normally not engaged unless you are cutting threads.

I really think you should consider tearing the lathe apart to clean and lube everything. You can do it with the parts manual below. Leave the spindle and headstock alone unless there is a problem but everything else can be taken apart and cleaned out. This will be good for the lathe and good for you because you'll learn a lot about your lathe.

I also suggest you join the Yahoo Emco Larger Lathes group. Lots of info and help there.

Attachments

I appreciate the help Mike ... looks rather involved.  Naturally I'll give it a shot and clean everything up. Was hoping it would be something simpler and less work.

Naturally I'll give it a shot and clean everything up. Was hoping it would be something simpler and less work.

Thanks for the suggestion. I used to belong to the EMCO group and many other Yahoo groups. I really hate the 'format' of the Yahoo groups (unless something has changed). Even the dial up BBS days in the 80's blow away the Yahoo group format.

Even though I'm not a machinist I've made quite a few things with my lathe and mill. Hopefully I'll get this straightened out before I croak and can get back into turning some interesting things.

https://www.pbase.com/smokedaddy/unitron_pier&page=all

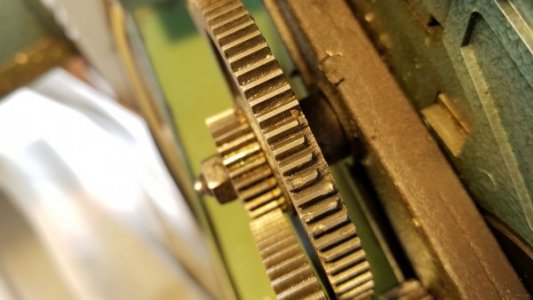

Oh, BTW, I assume we're talking about this part?

Thanks for the suggestion. I used to belong to the EMCO group and many other Yahoo groups. I really hate the 'format' of the Yahoo groups (unless something has changed). Even the dial up BBS days in the 80's blow away the Yahoo group format.

Even though I'm not a machinist I've made quite a few things with my lathe and mill. Hopefully I'll get this straightened out before I croak and can get back into turning some interesting things.

https://www.pbase.com/smokedaddy/unitron_pier&page=all

Oh, BTW, I assume we're talking about this part?

- Joined

- Apr 30, 2015

- Messages

- 11,445

Nice little lathe you have there- I wanted one of those decades ago when they were still making them.

I agree with you about the Yahoo group format, very hard to navigate

Mark

I agree with you about the Yahoo group format, very hard to navigate

Mark

I agree with you about the Yahoo group format, very hard to navigate

Mark

... that's why I came here.

- Joined

- Dec 20, 2012

- Messages

- 9,422

Yeah, item 22. It tends to break if you crash but can let go just from metal fatigue over time. It is light aluminum and I think you can turn one from the stuff from the hardware store.

You made some neat stuff there, JWW. Your call on the tear down. If it was me, I would do it to make sure it serves me well for the next several decades. Good luck.

- Joined

- Oct 27, 2013

- Messages

- 57

Hi Mark, sorry but I most defiantly do not agree that tightening by hand is sufficient !I agree with the chuck removal technique, but not re-mounting with a wrench- tightening by hand should be sufficient

M

It is VERY important that the chuck is tightened with a wrench or similar, yes during use it will/should tighten due to the cutting action but suppose you were only cutting small diameter at high speed - the torque is very small and will not tighten the chuck sufficiently to resist the kinetic energy stored when you stop the spindle.

I have been using machines both hobby and early industrial with screw on chucks for over 60 years and believe me it gets quite exciting [and expensive] when one come loose - never happened to me my early mentors made sure of that.

Modern industrial and indeed many hobby machines now use better mounting methods

John