- Joined

- Nov 3, 2022

- Messages

- 66

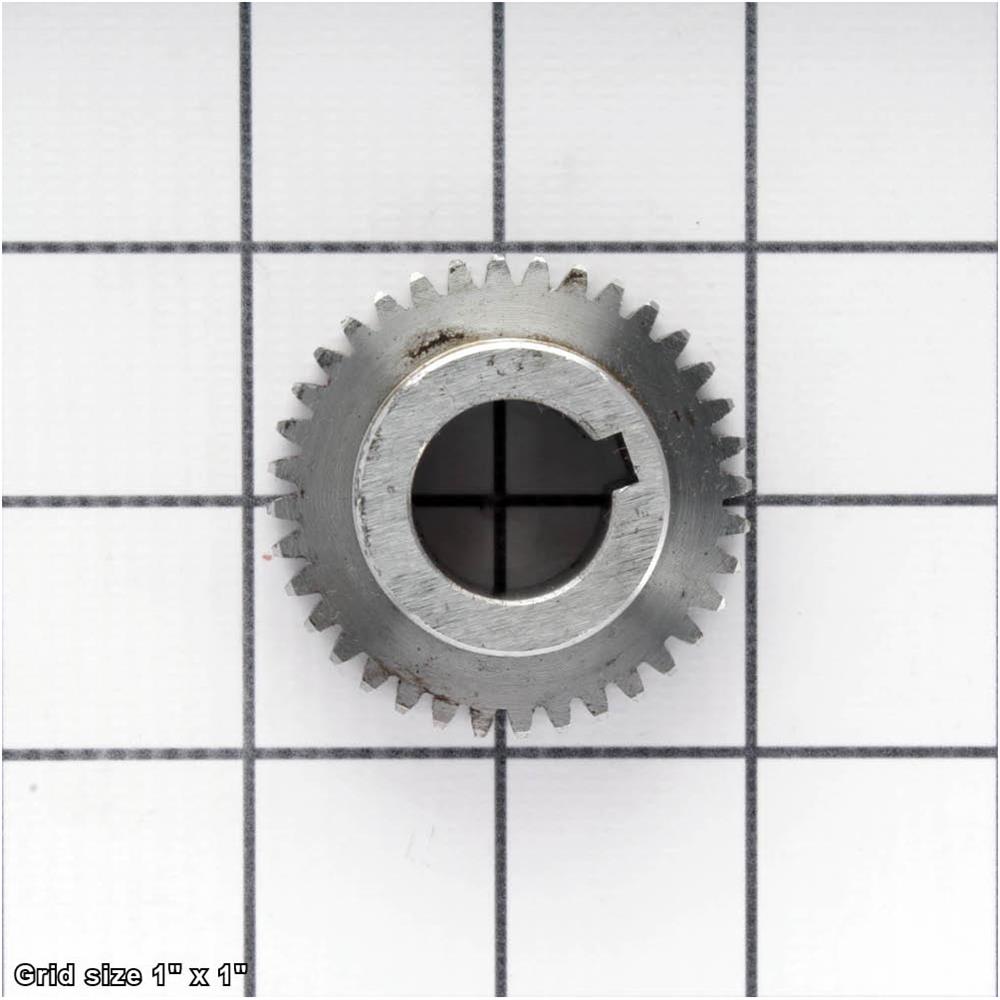

So I bought a 96' Enco 12x36 110-2079 lathe with no metric change gears. It only has 40t, 80t, 40t...which according to the manual would be for standard pitch threads...that's all well and good.

My question is this. I'm trying to confirm if the grizzly g4003 or g4003g metric change gears would work as they are practically the same lathe with some electrical differences and other odd and ends.

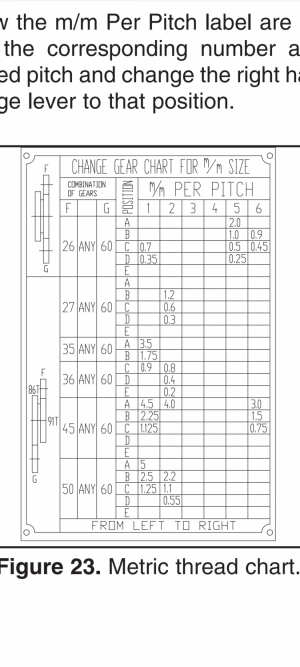

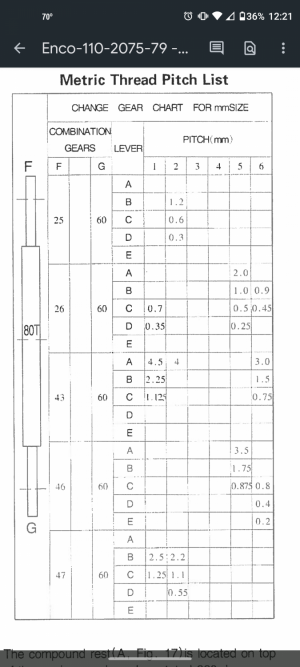

Here I will post a screen shot of the enco manual and a shot of the grizzly g4003 manual.

The cleaner newer image is grizzly.

Any insight would help. I'd like the ability to do both thread styles.

My question is this. I'm trying to confirm if the grizzly g4003 or g4003g metric change gears would work as they are practically the same lathe with some electrical differences and other odd and ends.

Here I will post a screen shot of the enco manual and a shot of the grizzly g4003 manual.

The cleaner newer image is grizzly.

Any insight would help. I'd like the ability to do both thread styles.