- Joined

- Sep 22, 2010

- Messages

- 7,223

Reprinted with permission from Neil Butterfield

Original at http://www.nbutterfield.com/Pages/ER40ColletChuck.aspx

See Neil's store at http://www.neilsniche.com/Pages/default.aspx

ER40 Collet Chuck

When I first saw this construction article in the February/March 2015 issue of Machinist's Workshop magazine I knew I had to make one. I had heard about ER collets but I did not know of the most significant advantage, there are no gaps in the range of material sizes that they can hold. ER40 collets are made in 1 mm steps from 3 mm to 30 mm and each spans 1 mm. In contrast, a 5C collet has a limited holding range of less than +.010" to -.010". With the set of 23 ER40 collets I purchased I cover 1/8" to 1" with no gaps. The collets are marked in imperial dimensions (inches) not metric.

Years ago I had made a spindle mounted 5C collet holder for my 9" South Bend lathe but I was never that happy with it. I didn't do a very good job making it. Primarily the problem was in the fit of the collet holder counter bore and the lathe spindle shoulder. I also did not like the fact that I had to use a draw bar along with a collet internal threaded plug to clamp the 5C collet which prevented extending a long work piece through the small 3/4" spindle bore.

ER (extended range) collets were originally designed by a Swiss company and were used principally for tool holding. Lathe work holding seems a better use to me with the no gap feature. I never liked collets for holding end mills. My mentor, an old time tool and die maker, always said "why do you think the manufacturers put a flat on those end mills"? Hence the very common end mill holders. I have no milled grooves in my milling machine table. I'm told that even expensive CNC collets will let slip an end mill on occasion.

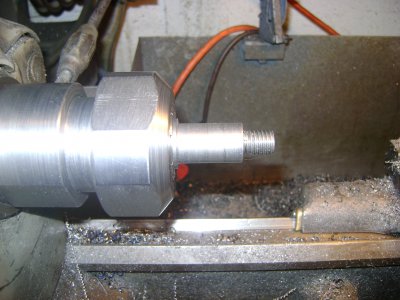

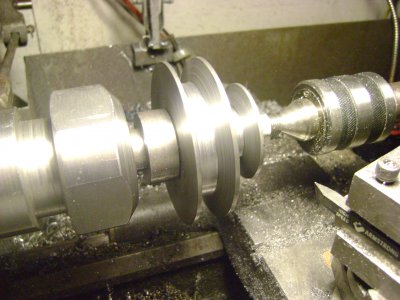

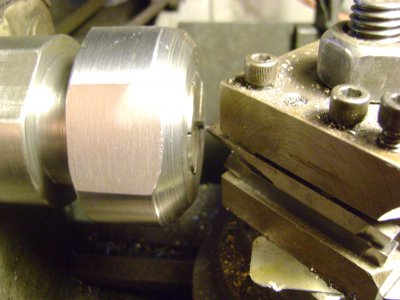

The ER collet chuck only requires two parts, the chuck body which I made and the clamping ring or nut, which I purchased. The chuck body has a 1-1/2"- 8 threaded mount and a M50 x 1.5 metric thread for the metric collet nut. The collet nut is readily available from the collet manufacturers and much less expensive to purchase than to single point turn the metric thread on the collet chuck body. I have the capability to cut metric threads on my South Bend lathe but if one does not have the necessary gears, the Machinist's Workshop article tells how to cut a 99.8% accurate metric thread with readily available inexpensive standard lathe gears. This chuck could easily be made to fit lathes other than the 1-1/2" spindle lathe described in the Machinist's Workshop article discussed here.

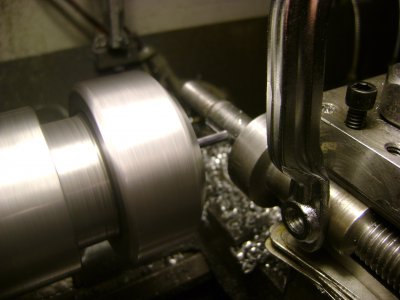

To machine the 8° collet seat I set the angle of my compound using a sine bar resulting in a very accurate machined seat. No taper attachment required. I have a compound setting block I made some time ago which makes it very quick and easy to machine very accurate tapers. I've never used or needed a taper attachment and never understood why anyone would want such a complex piece of lathe equipment.

I learned that very accurate ER collets can be very expensive, up to $800 for a set to be used on an expensive multi-axis CNC machine. I opted for a new imported set on eBay. I paid $132 for my 23 piece 1/8" to 1" set, less than $6 each. Included with the collets was a collet nut spanner wrench for $18 and a MT 3 arbor collet chuck with the collet nut for $46. I purchased the MT 3 collet chuck mainly for the collet nut but it was nice to have to check my metric thread. With the MT 3 arbor I can also use my milling machine or it will even fit my South Bend spindle.

I've always wondered, and never found an answer, why the ER40 collet set is sold with only 23 collets and not the 29 that are necessary for a complete set in 32nds. which would be 29 collets. When I buy a set I want the complete set so since purchasing the 23 pc. set I found a source and purchased the missing 6 collets. Purchased from www.boltontools.com for $6.95 each. they have other size ER's also. I'll probably never use them but now I have a complete set. I've changed my collet drawer to accommodate the extra 6 collets.

Upon completion of this collet chuck I was pleasantly surprised. The accuracy (work piece run out) on a number of test pieces was from zero to .0015" with .0005" to .001"the norm. Hefty tightening of the collet nut and very clean collet slots is important. I know that I will be using it often and frequently using instead of my trusty 5" well worn and not very accurate, 3-jaw chuck.

Also, with this Collet Chuck I can use long material pieces up to 3/4" diameter through the spindle very accurately and shorter material up to 1' diameter very accurately.

For small work, under 1/2" I still have my very accurate 3C collets available with through the spindle capability of 1/2". But the 3C collets like the 5C, have gaps between the standard fractional sizes. Fortunately I have some 3C hex collets which I use often and they are not available in the ER system. Probably because of the 16 slots.

For those of you not familiar with the ER collet system the collet nut, or clamping ring, has a 30° conical feature to engage the collet along with a cam feature to extract the collet. The selected collet is inserted in the collet nut first in a tillting fashion to engage the collet groove and then when the collet nut is removed from the chuck the collet is retained with the nut, preventing dropping the collet. Very nice for we clumsy old farts.

Below is the Collet Chuck with the Nut installed along with

the two spanner wrenches required, 4 typical collets and

the Machinist's Workshop feature issue

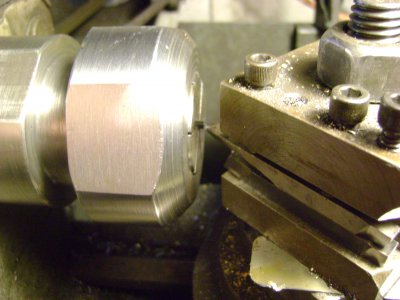

Mounted on my 9" South Bend lathe holding a piece of brass round

Spanner wrench to install the chuck on lathe 1-1/2-8 threaded spindle

Spanner for the Collet Chuck Nut

My 23 ER40 collets, 1/8" to 1"

Original at http://www.nbutterfield.com/Pages/ER40ColletChuck.aspx

See Neil's store at http://www.neilsniche.com/Pages/default.aspx

ER40 Collet Chuck

When I first saw this construction article in the February/March 2015 issue of Machinist's Workshop magazine I knew I had to make one. I had heard about ER collets but I did not know of the most significant advantage, there are no gaps in the range of material sizes that they can hold. ER40 collets are made in 1 mm steps from 3 mm to 30 mm and each spans 1 mm. In contrast, a 5C collet has a limited holding range of less than +.010" to -.010". With the set of 23 ER40 collets I purchased I cover 1/8" to 1" with no gaps. The collets are marked in imperial dimensions (inches) not metric.

Years ago I had made a spindle mounted 5C collet holder for my 9" South Bend lathe but I was never that happy with it. I didn't do a very good job making it. Primarily the problem was in the fit of the collet holder counter bore and the lathe spindle shoulder. I also did not like the fact that I had to use a draw bar along with a collet internal threaded plug to clamp the 5C collet which prevented extending a long work piece through the small 3/4" spindle bore.

ER (extended range) collets were originally designed by a Swiss company and were used principally for tool holding. Lathe work holding seems a better use to me with the no gap feature. I never liked collets for holding end mills. My mentor, an old time tool and die maker, always said "why do you think the manufacturers put a flat on those end mills"? Hence the very common end mill holders. I have no milled grooves in my milling machine table. I'm told that even expensive CNC collets will let slip an end mill on occasion.

The ER collet chuck only requires two parts, the chuck body which I made and the clamping ring or nut, which I purchased. The chuck body has a 1-1/2"- 8 threaded mount and a M50 x 1.5 metric thread for the metric collet nut. The collet nut is readily available from the collet manufacturers and much less expensive to purchase than to single point turn the metric thread on the collet chuck body. I have the capability to cut metric threads on my South Bend lathe but if one does not have the necessary gears, the Machinist's Workshop article tells how to cut a 99.8% accurate metric thread with readily available inexpensive standard lathe gears. This chuck could easily be made to fit lathes other than the 1-1/2" spindle lathe described in the Machinist's Workshop article discussed here.

To machine the 8° collet seat I set the angle of my compound using a sine bar resulting in a very accurate machined seat. No taper attachment required. I have a compound setting block I made some time ago which makes it very quick and easy to machine very accurate tapers. I've never used or needed a taper attachment and never understood why anyone would want such a complex piece of lathe equipment.

I learned that very accurate ER collets can be very expensive, up to $800 for a set to be used on an expensive multi-axis CNC machine. I opted for a new imported set on eBay. I paid $132 for my 23 piece 1/8" to 1" set, less than $6 each. Included with the collets was a collet nut spanner wrench for $18 and a MT 3 arbor collet chuck with the collet nut for $46. I purchased the MT 3 collet chuck mainly for the collet nut but it was nice to have to check my metric thread. With the MT 3 arbor I can also use my milling machine or it will even fit my South Bend spindle.

I've always wondered, and never found an answer, why the ER40 collet set is sold with only 23 collets and not the 29 that are necessary for a complete set in 32nds. which would be 29 collets. When I buy a set I want the complete set so since purchasing the 23 pc. set I found a source and purchased the missing 6 collets. Purchased from www.boltontools.com for $6.95 each. they have other size ER's also. I'll probably never use them but now I have a complete set. I've changed my collet drawer to accommodate the extra 6 collets.

Upon completion of this collet chuck I was pleasantly surprised. The accuracy (work piece run out) on a number of test pieces was from zero to .0015" with .0005" to .001"the norm. Hefty tightening of the collet nut and very clean collet slots is important. I know that I will be using it often and frequently using instead of my trusty 5" well worn and not very accurate, 3-jaw chuck.

Also, with this Collet Chuck I can use long material pieces up to 3/4" diameter through the spindle very accurately and shorter material up to 1' diameter very accurately.

For small work, under 1/2" I still have my very accurate 3C collets available with through the spindle capability of 1/2". But the 3C collets like the 5C, have gaps between the standard fractional sizes. Fortunately I have some 3C hex collets which I use often and they are not available in the ER system. Probably because of the 16 slots.

For those of you not familiar with the ER collet system the collet nut, or clamping ring, has a 30° conical feature to engage the collet along with a cam feature to extract the collet. The selected collet is inserted in the collet nut first in a tillting fashion to engage the collet groove and then when the collet nut is removed from the chuck the collet is retained with the nut, preventing dropping the collet. Very nice for we clumsy old farts.

Below is the Collet Chuck with the Nut installed along with

the two spanner wrenches required, 4 typical collets and

the Machinist's Workshop feature issue

Mounted on my 9" South Bend lathe holding a piece of brass round

Spanner wrench to install the chuck on lathe 1-1/2-8 threaded spindle

Spanner for the Collet Chuck Nut

My 23 ER40 collets, 1/8" to 1"