I have never built a CNC machine, and it has been years (10+) since I have played around with one. I'm 30, and I am a Flight Engineer / Pilot (not an EE, I don't do industrial automation for work, etc.).

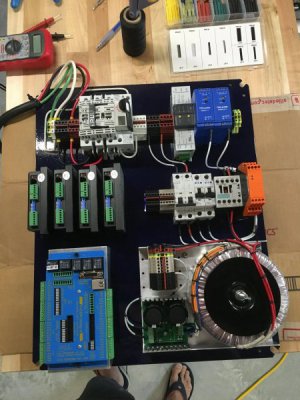

I grew up around airplanes, and I may have a few engineering courses under my belt. The machine is in the drafting phase, and the electronics (the heart) are starting to come together.

System voltage input: 240VAC split phase

Control/Safety Voltage: 120VAC, 24VDC

Motion Control Voltage: 5VDC

Stepper Voltage: 65VDC

Motion Control: Hicon Integra 6-axis motion controller

Stepper Drivers x4: Kelling KL8056

Currently planning Nema23 425oz-in 8 wire Steppers (on hand) - not 100% sure this will be sufficient for all axis.

Safety: Dold Safety Relay (controls main contactor)

-E-stop

-Start/Stop switches

The Teaser:

(Shop Approved footwear?)

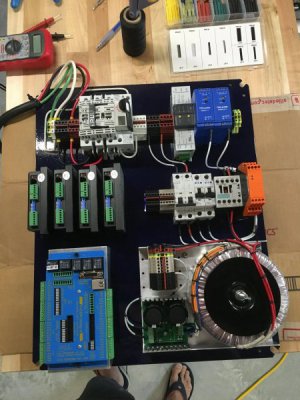

I grew up around airplanes, and I may have a few engineering courses under my belt. The machine is in the drafting phase, and the electronics (the heart) are starting to come together.

System voltage input: 240VAC split phase

Control/Safety Voltage: 120VAC, 24VDC

Motion Control Voltage: 5VDC

Stepper Voltage: 65VDC

Motion Control: Hicon Integra 6-axis motion controller

Stepper Drivers x4: Kelling KL8056

Currently planning Nema23 425oz-in 8 wire Steppers (on hand) - not 100% sure this will be sufficient for all axis.

Safety: Dold Safety Relay (controls main contactor)

-E-stop

-Start/Stop switches

The Teaser:

(Shop Approved footwear?)

Last edited:

Looking forward to watching your build.

Looking forward to watching your build.