- Joined

- Jan 14, 2013

- Messages

- 290

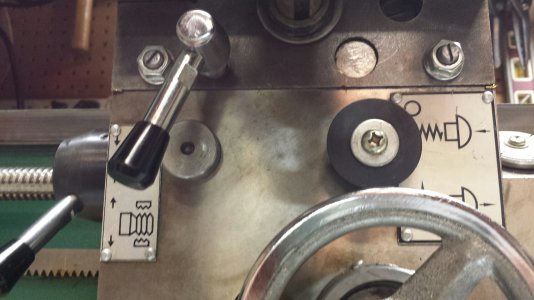

Can you post a pic of the back side of the half nut?

Is it held in place with a cross pin?

Looking at the manual, that lathe only uses one piece of what most is commonly known as a set. If so then its going to wear out rather fast because it is pushing /ridding and not clamping the leadscrew as half nuts are designed to do.

Folks have been making half nut from derlin/actel. The projects in metal group seem to be having success from what I have read,

so that might be a possible solution for you to look into.

Your leadscrew is 6 tpi

Is it held in place with a cross pin?

Looking at the manual, that lathe only uses one piece of what most is commonly known as a set. If so then its going to wear out rather fast because it is pushing /ridding and not clamping the leadscrew as half nuts are designed to do.

Folks have been making half nut from derlin/actel. The projects in metal group seem to be having success from what I have read,

so that might be a possible solution for you to look into.

Your leadscrew is 6 tpi

Last edited:

the halfnut thread wear appears to be primarily on the outside of the thread if so I am thing that the halfnut needs to be closer to the lead screw.

the halfnut thread wear appears to be primarily on the outside of the thread if so I am thing that the halfnut needs to be closer to the lead screw.