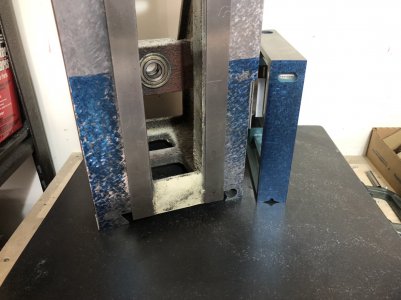

Roughing in the back ways, they’re a freaking disaster from the factory. Started out with about 20-25 thousands of wallow.

Still can’t understand how could the factory have produced something this bad. Like I said, the machine ground surfaces aren’t bad, it the hand finished ones that are a disaster.

Tried an angle grinder and wasn’t having much luck, but your mileage will vary. If I tried to just dust the high spots, grinder wasn’t really moving more material than heavy scraper push. And I was afraid to push the grinder for fear of digging in. I’m going to try a big file as some have suggested. But down to about 10 thousands now, its contacting evenly, just still have that big dip by the oil grove that I want to get rid of.