I won't be frequenting this board any longer, but I want to be fair to the people on this project. If you want the base and two clamps I made, please send me an email (echristley@att.net) with your address. I'll ship them to you. My expense. You can ship back the parts you made, if you like (and it would be appreciated). I'm moving, and would rather not move extra stuff. My machines will be offline for a couple months as I get a workshop built. After that, I will finish my copy of the indexer, incorporating any parts you choose to ship; otherwise, I'll build what is necessary to finish.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Group Project: Dividing Head - The Build

- Thread starter Flyinfool

- Start date

I received some very nice base pieces from Shotgun. Also the spindle clamp and worm mount.

I can see a lot of time went into these parts. My plan is to finish the rest over time.

I wanted to throw out a couple of ideas/issues to anyone still following this:

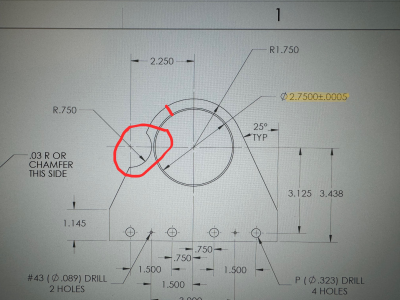

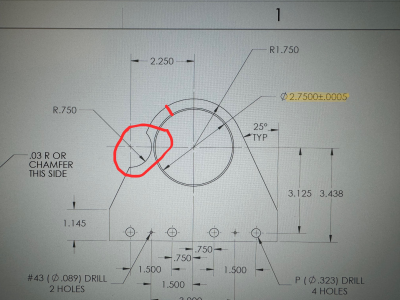

First- this base and auxiliary base have been machined with 3" holes for the trunnion but the plans call for 2.75". I am concerned about the downstream effects of trying to use these as is. For the base I am thinking of a bronze bushing with flange to get down to 2.75. This should be easier than other solutions and will improve movement. The aux base is definitely a problem as the 3" hole will intersect with the cutout to clear the gear shift. I will probably re-make this one part.

For the hole in the aux base, I don't see why it has to be so large? It is really just a pivot point. I am considering a smaller hole (1"?) Then I could use a solid bronze boss attached to the end of the trunnion and I would have bronze bearing surfaces at both ends. The trunnion is only clamped at the other end.

I have no idea how Shotgun clamped the base for machining the bottom surface! With the angle this is challenging!

Second- I need to buy a hunk of metal for the trunnion. I really want to find some 12L14 cause there is a ton of metal to remove. Obviously 1018 would be cheaper but might be a lot harder to work with.

I can see a lot of time went into these parts. My plan is to finish the rest over time.

I wanted to throw out a couple of ideas/issues to anyone still following this:

First- this base and auxiliary base have been machined with 3" holes for the trunnion but the plans call for 2.75". I am concerned about the downstream effects of trying to use these as is. For the base I am thinking of a bronze bushing with flange to get down to 2.75. This should be easier than other solutions and will improve movement. The aux base is definitely a problem as the 3" hole will intersect with the cutout to clear the gear shift. I will probably re-make this one part.

For the hole in the aux base, I don't see why it has to be so large? It is really just a pivot point. I am considering a smaller hole (1"?) Then I could use a solid bronze boss attached to the end of the trunnion and I would have bronze bearing surfaces at both ends. The trunnion is only clamped at the other end.

I have no idea how Shotgun clamped the base for machining the bottom surface! With the angle this is challenging!

Second- I need to buy a hunk of metal for the trunnion. I really want to find some 12L14 cause there is a ton of metal to remove. Obviously 1018 would be cheaper but might be a lot harder to work with.

Last edited:

I am not sure who is still following this thread. I hope at least Jeff @Flyinfool still is.

Anyway, I think I just stumbled onto a major design issue: As it is drawn, the dividing head will only work with the spindle axis vertical. Note that the worm drive shaft and gear shift must rotate with the trunnion and worm gear. The gear shift passes thru a notch cutout in the auxiliary base. Any attempt to rotate the trunnion will result in interference at this notch. I could be reading this incorrectly but I have looked at this for some time.

One solution would be to make the hole for the trunnion in the aux base smaller and make the trunnion boss correspondingly smaller. Then you could reduce the perimeter of the aux base to allow the gearshift to pass around it without a cutout. I do not know what other downstream effects this might have. I don't know how we did not see this.

You could also reduce the diameter of the gear shift at this location but I think we may need to do both.

Comments please?

Anyway, I think I just stumbled onto a major design issue: As it is drawn, the dividing head will only work with the spindle axis vertical. Note that the worm drive shaft and gear shift must rotate with the trunnion and worm gear. The gear shift passes thru a notch cutout in the auxiliary base. Any attempt to rotate the trunnion will result in interference at this notch. I could be reading this incorrectly but I have looked at this for some time.

One solution would be to make the hole for the trunnion in the aux base smaller and make the trunnion boss correspondingly smaller. Then you could reduce the perimeter of the aux base to allow the gearshift to pass around it without a cutout. I do not know what other downstream effects this might have. I don't know how we did not see this.

You could also reduce the diameter of the gear shift at this location but I think we may need to do both.

Comments please?

Last edited:

oopie, I wrote this on Tuesday shortly after your post, I just just forgot to hit the "Post Reply" button.

I see what you are saying.

I have a couple of ideas on how to fix this with the parts we have. Hang tight while I ponder this.

I see what you are saying.

I have a couple of ideas on how to fix this with the parts we have. Hang tight while I ponder this.

The attachment won't load for me.Heated the steel and cooled the bushing with dry ice. Dropped right in.View attachment 490431