- Joined

- Jul 18, 2017

- Messages

- 407

Hi Guys,

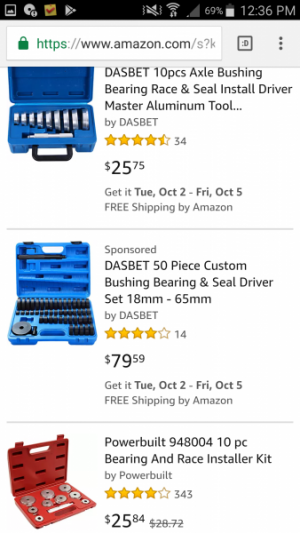

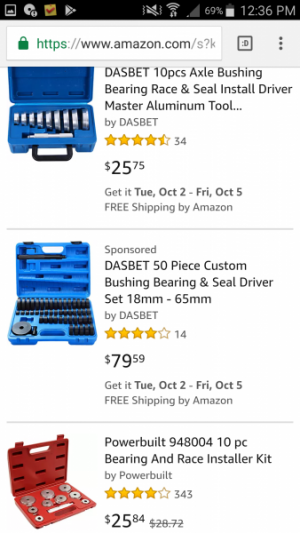

I have a nice Baldor dental lathe / polisher that where one spindle is making noise. I'd like to replace the bearings. I understand that I need a drift set to install the bearings properly. I went to amazon, and saw these type of kits (shown below). It seems like these kits were made for car bearings. The blue kit in the middle of the pic has more smaller parts than the other sets, but I am not sure if these were meant for small machine roller bearings. Am I looking at the wrong items for my application?

Thank you, for helping my helpless self ;-)

I have a nice Baldor dental lathe / polisher that where one spindle is making noise. I'd like to replace the bearings. I understand that I need a drift set to install the bearings properly. I went to amazon, and saw these type of kits (shown below). It seems like these kits were made for car bearings. The blue kit in the middle of the pic has more smaller parts than the other sets, but I am not sure if these were meant for small machine roller bearings. Am I looking at the wrong items for my application?

Thank you, for helping my helpless self ;-)