- Joined

- Jan 22, 2014

- Messages

- 578

I was trying to get something to look at by Easter Sunday but I'm not completely finished with the project yet. Naturally, I ran into unanticipated problems along the way.

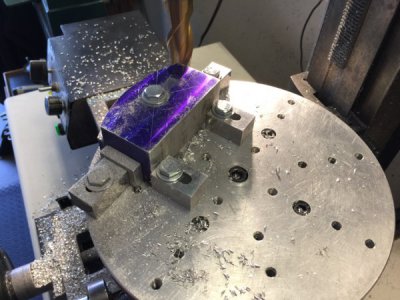

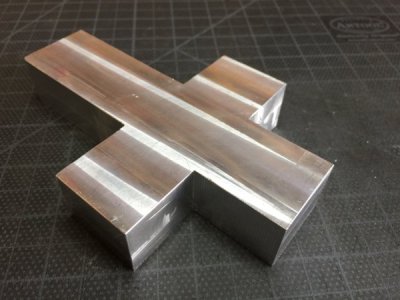

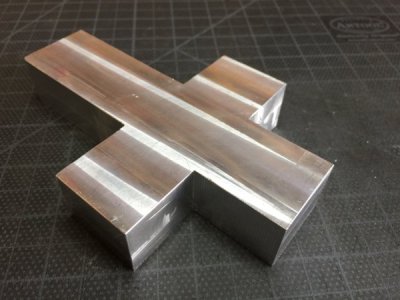

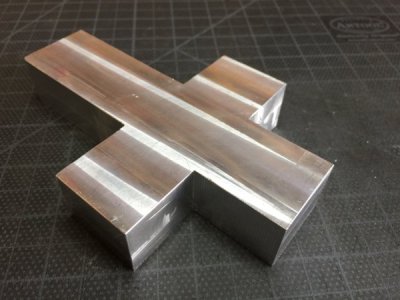

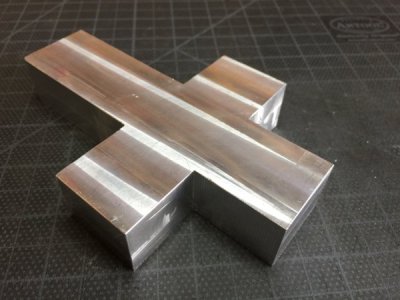

Anyway, I wanted to make a cross out of a single piece of 6061 so I shaved a 1' slice off a 3 1/2" square block. I band sawed and roughed out the basic shape to the largest dimension for the flutes, 1". Then I turned all four "legs" of the cross to .500" incorporating some other pleasing angles. I put it in the mill and cut flutes in the large ends and flats in the shanks for a special effect.

I left the pointy tips rough until last because I had put a minor "center" in them for keeping it true in the lathe or mill. I was planning on using my ball turner to finish the tips so after I did one (the only one possible) it turned out just as i had planed it. The problem came when I went to chuck the other 3 tips and the cross legs wouldn't clear the compound or the ball turner. So I came up with a split collar that worked great for holding the cross and I somehow managed to hand-cut the 3 remaining tips to match. As with all of my projects, no CNC was used to create this project.

I still haven't completed the finish or made a stand for this project, but it'll come to me in the next week of so.

Bandsaw (Taiwan)

Grizzly G0602

LMS MIni Mill w/ RT

ER25 Collet adapter plate

Rick

Anyway, I wanted to make a cross out of a single piece of 6061 so I shaved a 1' slice off a 3 1/2" square block. I band sawed and roughed out the basic shape to the largest dimension for the flutes, 1". Then I turned all four "legs" of the cross to .500" incorporating some other pleasing angles. I put it in the mill and cut flutes in the large ends and flats in the shanks for a special effect.

I left the pointy tips rough until last because I had put a minor "center" in them for keeping it true in the lathe or mill. I was planning on using my ball turner to finish the tips so after I did one (the only one possible) it turned out just as i had planed it. The problem came when I went to chuck the other 3 tips and the cross legs wouldn't clear the compound or the ball turner. So I came up with a split collar that worked great for holding the cross and I somehow managed to hand-cut the 3 remaining tips to match. As with all of my projects, no CNC was used to create this project.

I still haven't completed the finish or made a stand for this project, but it'll come to me in the next week of so.

Bandsaw (Taiwan)

Grizzly G0602

LMS MIni Mill w/ RT

ER25 Collet adapter plate

Rick

Last edited: