- Joined

- Jun 26, 2014

- Messages

- 619

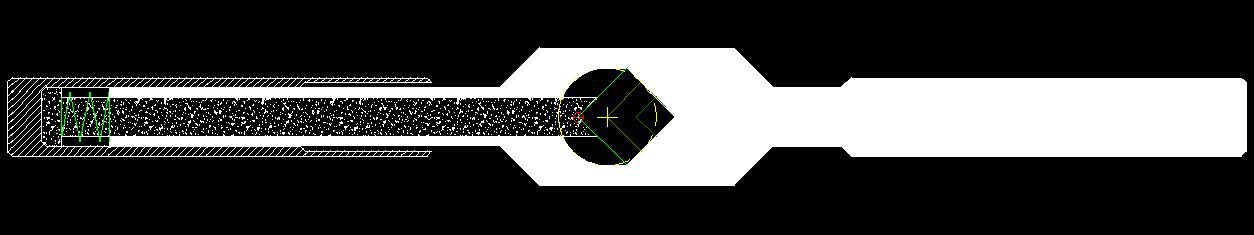

I have broken a couple of tap wrench over the years - while I have some good quality taps, all my tap wrenches are rubbish. So today I decided to try and build my own base on a blatant rip off of the Starrett No.91 style.

Started with a bit of 28mm dia. scrap round stock.

Turned down one end to 12mm dia, for the adjusting side handle.

and the other to 15mm dia. for the fixed handle.

Knurled the fixed handle.

and drilled the adjusting side handle for the plunger.

and that was the lathe work on the body complete

Started with a bit of 28mm dia. scrap round stock.

Turned down one end to 12mm dia, for the adjusting side handle.

and the other to 15mm dia. for the fixed handle.

Knurled the fixed handle.

and drilled the adjusting side handle for the plunger.

and that was the lathe work on the body complete