-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homemade taper attachment

- Thread starter HMF

- Start date

- Joined

- Feb 17, 2013

- Messages

- 4,406

Nels, have you been reading my mind?????

Just two days ago a wood turner friend of mine asked me if I wanted to do a "fun" project. She's turning wooden beads between tapered mandrels. The one for the headstock has a straight shaft, held precisely in an ER collet. The one for the tailstock locks into a Oneway live center with replaceable points, which use a #0 Morse taper. My task will be to machine this taper onto half the new mandrels, then machine a ~2 degree taper on the "business end" of all of them.

I've been considering how best to implement an offset center on my tailstock ... and here you go, posting an article about a taper attachment that should fit my 9x20 nicely!

Of course, while I'm at it, I must brag on my friend's talent. She's made her own set of mandrels, using 3/8" bolts she bought at Home Depot for raw material. Her idea was to find some steel that was relatively soft, so if she accidentally ran into it with a cutter, it would't damage the edge. And with just a file and her woodturning lathe, she's produced a pretty durn good 0MT taper on her own!!!!

Just two days ago a wood turner friend of mine asked me if I wanted to do a "fun" project. She's turning wooden beads between tapered mandrels. The one for the headstock has a straight shaft, held precisely in an ER collet. The one for the tailstock locks into a Oneway live center with replaceable points, which use a #0 Morse taper. My task will be to machine this taper onto half the new mandrels, then machine a ~2 degree taper on the "business end" of all of them.

I've been considering how best to implement an offset center on my tailstock ... and here you go, posting an article about a taper attachment that should fit my 9x20 nicely!

Of course, while I'm at it, I must brag on my friend's talent. She's made her own set of mandrels, using 3/8" bolts she bought at Home Depot for raw material. Her idea was to find some steel that was relatively soft, so if she accidentally ran into it with a cutter, it would't damage the edge. And with just a file and her woodturning lathe, she's produced a pretty durn good 0MT taper on her own!!!!

- Joined

- Sep 29, 2014

- Messages

- 2,102

I think I need one but the question comes up, will I be able to make it work with my older G9972 Grizzly lathe?

Don't know but it kinda makes me want to hang onto the old SB9C and add that to it for my own work.

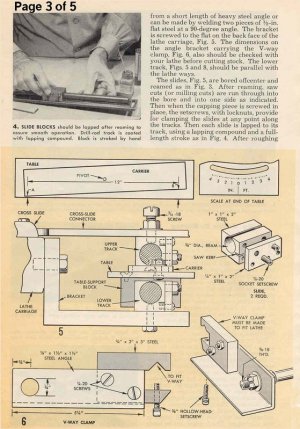

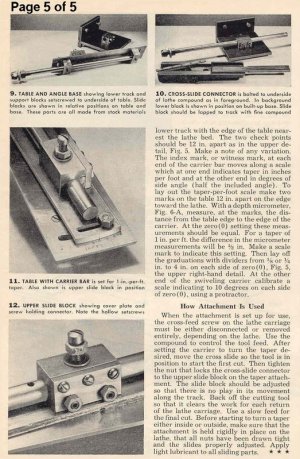

You can add a taper attachment to any lathe, however on a machine that was not built with this in mind you will need to disable the crossfeed leadscrew when using it. I had a Clausing 13 X 48 with a taper attachment, the crossfeed leadscrew had an internal spline that allowed the crosslide to move independent of the leadscrew.

- Joined

- Feb 17, 2013

- Messages

- 4,406

It's dead simple on the Grizzly G4000 (9x20 lathe). Just use a 5mm Allen wrench to remove the two screws holding the cross feed crank anchor. Crank it a few times to form a gap between the mount and the carriage, and you're good to go.