I'll keep that link for future use, thanks! Turns out the stuff that was in there wasn't too bad. I wiped it off, frayed it out a little and it fluffed right up. Twisted it together and stuffed it back in the recess. Ready for another 100 years of use.

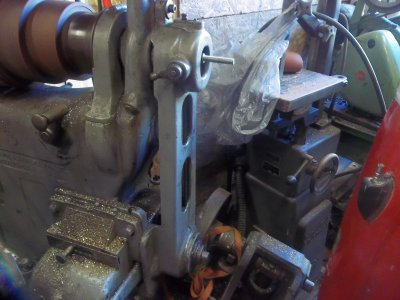

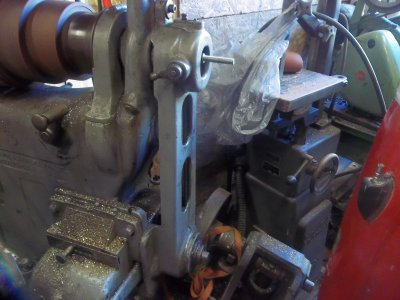

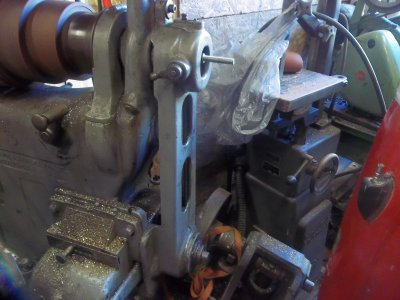

Here's some pictures of the re-assembly should someone stumble across this in the future.

Brass bearing first tightened from the inside to draw it in and take up the slop

Outer nut next

chain sprocket

Washer, it has a recess for tang that sticks out of the shaft

My friend, the spanner nut. Turns out this thing was hardened. I couldn't drill it for new holes. I guess when it has to come apart again 50 years from now someone will have to figure it out. My guess is if I had tightened the inner spanner nut before taking this apart it probably would not have been as tight. As is was, everything was jammed up against it.

Chain

Cover

She's been humming away for the last couple hours. I was bummed out when the machine went down, but I actually feel better now because I know more about the machine, am less intimidated by it and have more confidence for future repairs. Good day all-in-all.

Thanks for everyones' input.