-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How Should I Machine This?

- Thread starter Metal

- Start date

- Joined

- Feb 8, 2014

- Messages

- 11,144

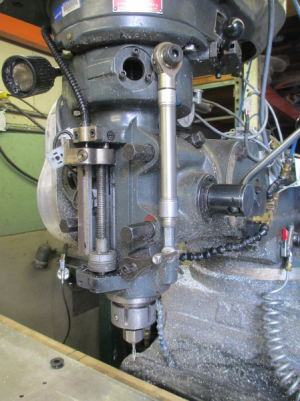

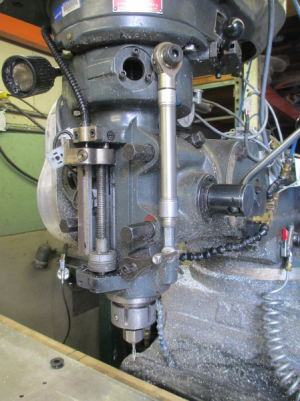

Nice installation!  Is that a NEMA 42 motor on the Z? It looks huge! How are you counterbalancing the quill to compensate for the backlash in the rack & pinion?

Is that a NEMA 42 motor on the Z? It looks huge! How are you counterbalancing the quill to compensate for the backlash in the rack & pinion?

Some lube is better than none. More is better

Is that a NEMA 42 motor on the Z? It looks huge! How are you counterbalancing the quill to compensate for the backlash in the rack & pinion?

Is that a NEMA 42 motor on the Z? It looks huge! How are you counterbalancing the quill to compensate for the backlash in the rack & pinion?Some lube is better than none. More is better

Thats easy, I don't, since I only cut conventional and down ramping I don't seem to need to (or haven't run into it yet!), I do leave the plunge brake partially down to give it a little more resistance, but otherwise nothing special. My plan was, in the distant future is it appears that I can slave axis's together in mach3, I could run a breakout board output to a relay of some sort, to a solenoid and have a little pneumatic cylinder engage/disengage the axis lock whenever that axis isn't moving, but that may be over complicating things.

Thats way after tuning it in, turns out that a scribe in a 1/8" collet is pretty concentric but I cant edgefind with it to save my life, or something else is still off, the tuning continues

Thats way after tuning it in, turns out that a scribe in a 1/8" collet is pretty concentric but I cant edgefind with it to save my life, or something else is still off, the tuning continues

- Joined

- Feb 8, 2014

- Messages

- 11,144

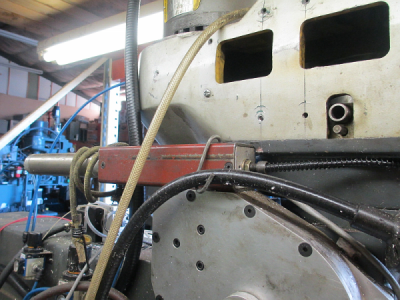

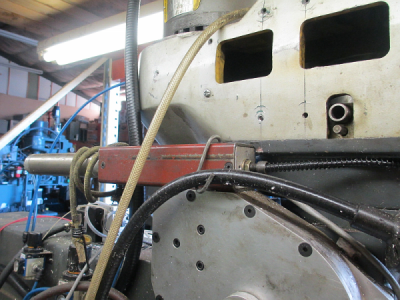

Here is a picture of my quill lock and the counterbalance cable connected to the quill stop. The other end of the counterbalance cable is connected to a 1.5 inch air cylinder. With the quill counterbalance, the Z will consistently hold 0.0001 (one tenth). I have not implemented the quill lock yet. I have all of the parts, but haven't been in a big hurry to get it finished.

- Joined

- Feb 8, 2014

- Messages

- 11,144

Yes, air spring, I kinda misspoke there.  It is 1.562, double acting, air cylinder, with air plumbed to the rod end, with a filter on the back end. The airline from the regulator is T'd to about a 3 gallon air tank to keep a large air reservoir so the pressure stays constant, rather than relying on the regulator alone. I run it about 35 PSI or more if needed for larger endmills. The 2 inch square tube housing in front of the cylinder is where the cable to cylinder connection is made. The assembly is attached to the top of the Z axis drive gear case. The cable is about half of a Yamaha Banshee brake cable.

It is 1.562, double acting, air cylinder, with air plumbed to the rod end, with a filter on the back end. The airline from the regulator is T'd to about a 3 gallon air tank to keep a large air reservoir so the pressure stays constant, rather than relying on the regulator alone. I run it about 35 PSI or more if needed for larger endmills. The 2 inch square tube housing in front of the cylinder is where the cable to cylinder connection is made. The assembly is attached to the top of the Z axis drive gear case. The cable is about half of a Yamaha Banshee brake cable.

It is 1.562, double acting, air cylinder, with air plumbed to the rod end, with a filter on the back end. The airline from the regulator is T'd to about a 3 gallon air tank to keep a large air reservoir so the pressure stays constant, rather than relying on the regulator alone. I run it about 35 PSI or more if needed for larger endmills. The 2 inch square tube housing in front of the cylinder is where the cable to cylinder connection is made. The assembly is attached to the top of the Z axis drive gear case. The cable is about half of a Yamaha Banshee brake cable.

It is 1.562, double acting, air cylinder, with air plumbed to the rod end, with a filter on the back end. The airline from the regulator is T'd to about a 3 gallon air tank to keep a large air reservoir so the pressure stays constant, rather than relying on the regulator alone. I run it about 35 PSI or more if needed for larger endmills. The 2 inch square tube housing in front of the cylinder is where the cable to cylinder connection is made. The assembly is attached to the top of the Z axis drive gear case. The cable is about half of a Yamaha Banshee brake cable.

- Joined

- Feb 8, 2014

- Messages

- 11,144

That sucks

Oh BTW, I keep the quill counterbalance pressurized all the time. At about 35 PSI it has about 50 lbs of up force. Hardly noticeable when operating manually, just makes a nice quill return.

Oh BTW, I keep the quill counterbalance pressurized all the time. At about 35 PSI it has about 50 lbs of up force. Hardly noticeable when operating manually, just makes a nice quill return.

Yeah I have no idea what caused it, I'm running 2 motors off of a 72v 20a power supply so it shouldn't have even been able to output enough power to burn up the controller, and it did it to the Y axis, while it was stationary and the X axis was slowly coming in to touch my finger (testing out a probe) I've already shot gecko an email for repair/advice on what caused this and ordered a replacement (should have a spare anyway)

Also found out my one shot lube system isn't delivering lube to all the points properly, ugh its always something isn't it

does that replace your clock spring(?) I'm also noticing a hole in your head which leads to what I assume is the gearhead. shouldn't that whole compartment be more or less full of oil?

Also found out my one shot lube system isn't delivering lube to all the points properly, ugh its always something isn't it

does that replace your clock spring(?) I'm also noticing a hole in your head which leads to what I assume is the gearhead. shouldn't that whole compartment be more or less full of oil?