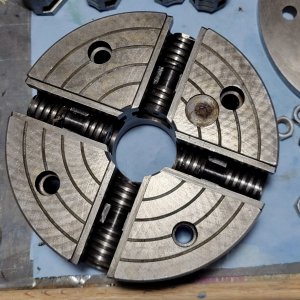

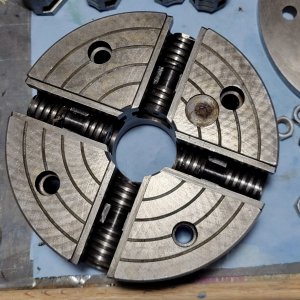

I'm cleaning out my 6" 4-jaw chuck; it came with my lathe and I've never used it before. Got the whole thing disassembled and cleaned up, but now see that I really need to get the operating screws out and clean them and around them as well, also to get grease in there. Are the parts on either side of each screw's center area wedges? How are they removed? I've watched every video I can find but either they don't show this step or those chucks don't have them.

Many thanks,

Tim

Many thanks,

Tim