- Joined

- Oct 29, 2023

- Messages

- 79

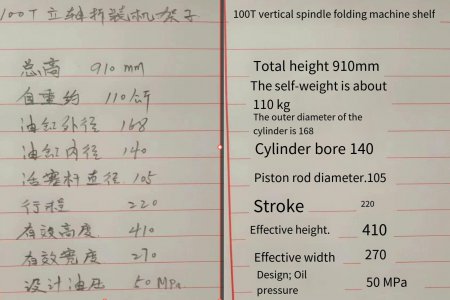

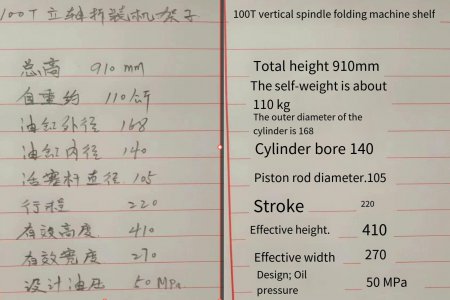

When I have difficulties in the processing of hexagonal or other polygons with inner holes, I think I can try hot stamping. So purchased a car maintenance side of the hydraulic press rack. Nominal 100T, I will not calculate, but I will check the relevant information. Here are some images:

I customized two hydraulic pipes based on the type of joint

As I progressed, I found more questions:

Solenoid valve electromagnet core can not move, probably because after a long time to stop the use of a little stuck, I can only open and clean up, now the valve body is also easy to use.

Another major problem was that the hydraulic cylinder began to leak oil after starting, and the oil leak point came from the hollow inside of the hydraulic push rod, and the specific leak point could not be observed. The final decision was to return the product to the seller and replace a 150T pressure hydraulic press frame.

I hope there are professional hydraulic practitioners here to answer some of my questions: the piston diameter of this hydraulic cylinder is 140mm, and the design input pressure is 50MPA, which is calculated according to my understanding: 7*7*3.14=153.86*500bar=76930/1000=76T. But the nominal pressure of this hydraulic cylinder is: 100T,

Is this my miscalculation? Or the calculation method is wrong? Or is this a nominal error?

I customized two hydraulic pipes based on the type of joint

As I progressed, I found more questions:

Solenoid valve electromagnet core can not move, probably because after a long time to stop the use of a little stuck, I can only open and clean up, now the valve body is also easy to use.

Another major problem was that the hydraulic cylinder began to leak oil after starting, and the oil leak point came from the hollow inside of the hydraulic push rod, and the specific leak point could not be observed. The final decision was to return the product to the seller and replace a 150T pressure hydraulic press frame.

I hope there are professional hydraulic practitioners here to answer some of my questions: the piston diameter of this hydraulic cylinder is 140mm, and the design input pressure is 50MPA, which is calculated according to my understanding: 7*7*3.14=153.86*500bar=76930/1000=76T. But the nominal pressure of this hydraulic cylinder is: 100T,

Is this my miscalculation? Or the calculation method is wrong? Or is this a nominal error?