I've had my 20 HF press since around 2002. It has never given me any trouble. Having said that, I always noticed the ram was crooked which made pressing straight a little challenging. The plates were cast and I never trusted them. After reading on a few websites about plates breaking, my suspicions were confirmed. I posted another thread about carbide taps showing what I did for replacing the plates.

I thought I would take a stab at upgrading the old press. The goal was to not weaken the high stress points of the press with heat or holes.

First off was straighten the ram. I cut the welds that add stability. I used the slitting saw on the mill because it removes such a small amount of metal.

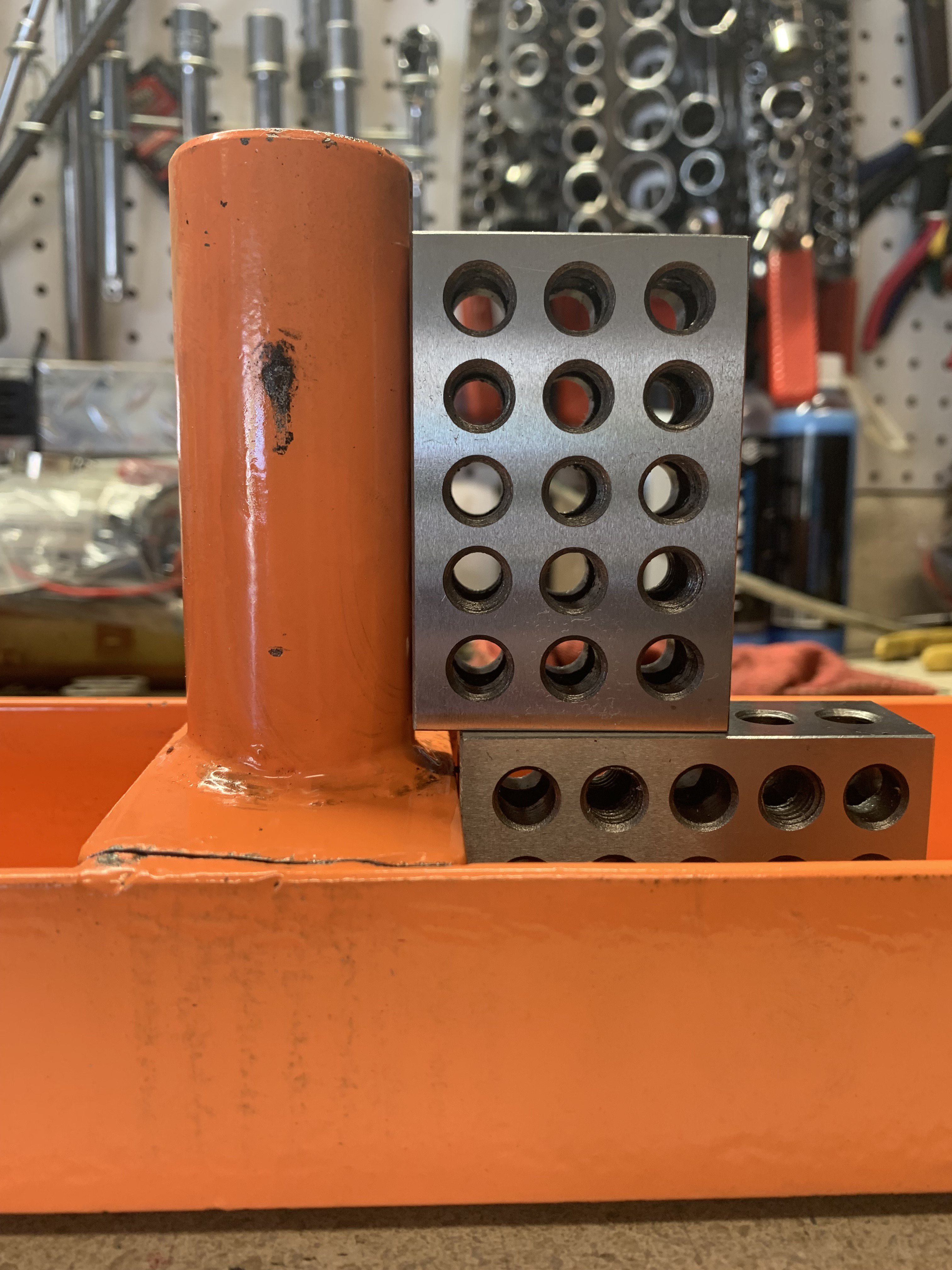

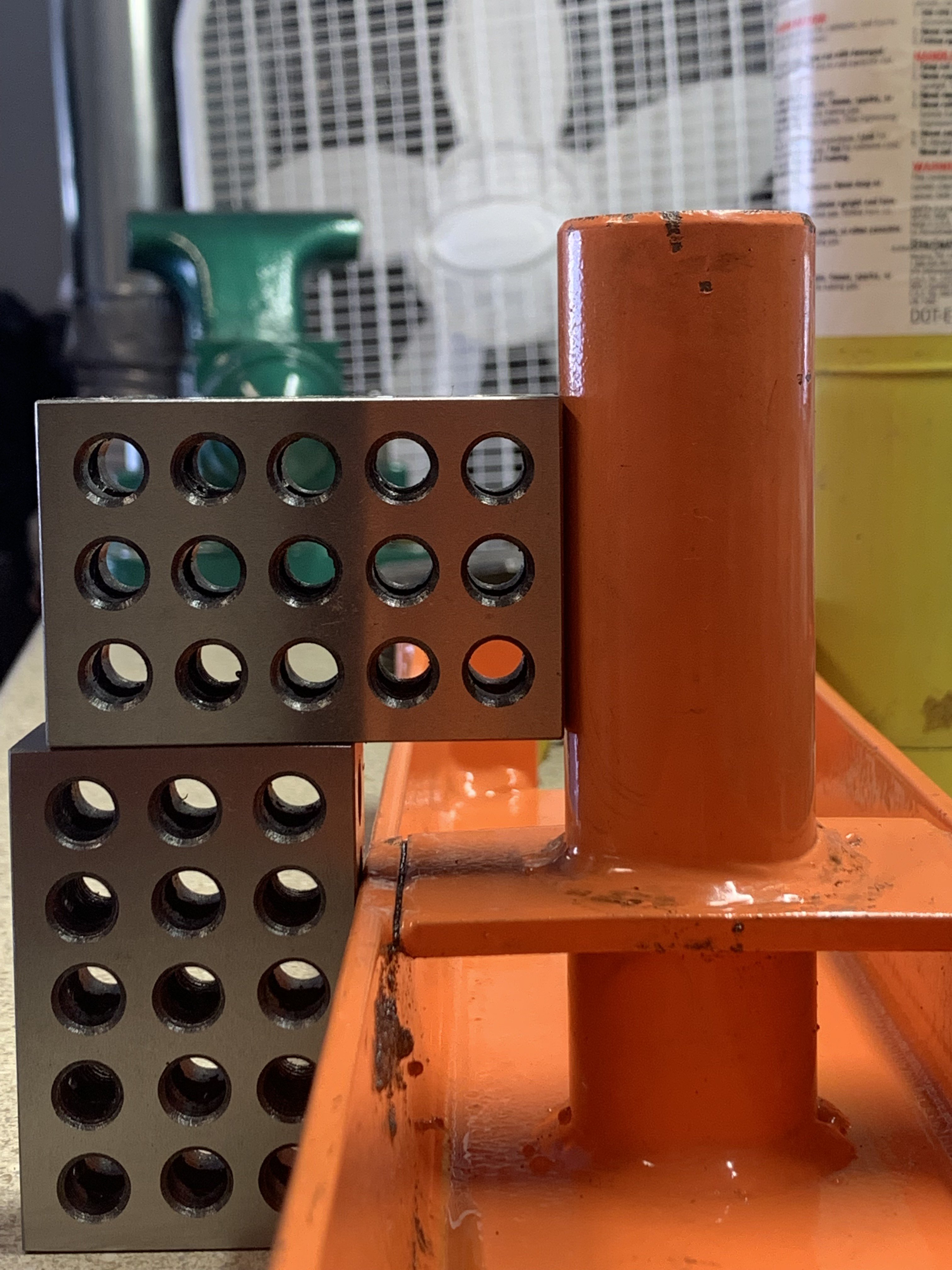

Then pounded on the ram with a sledge and a block of wood to find straight:

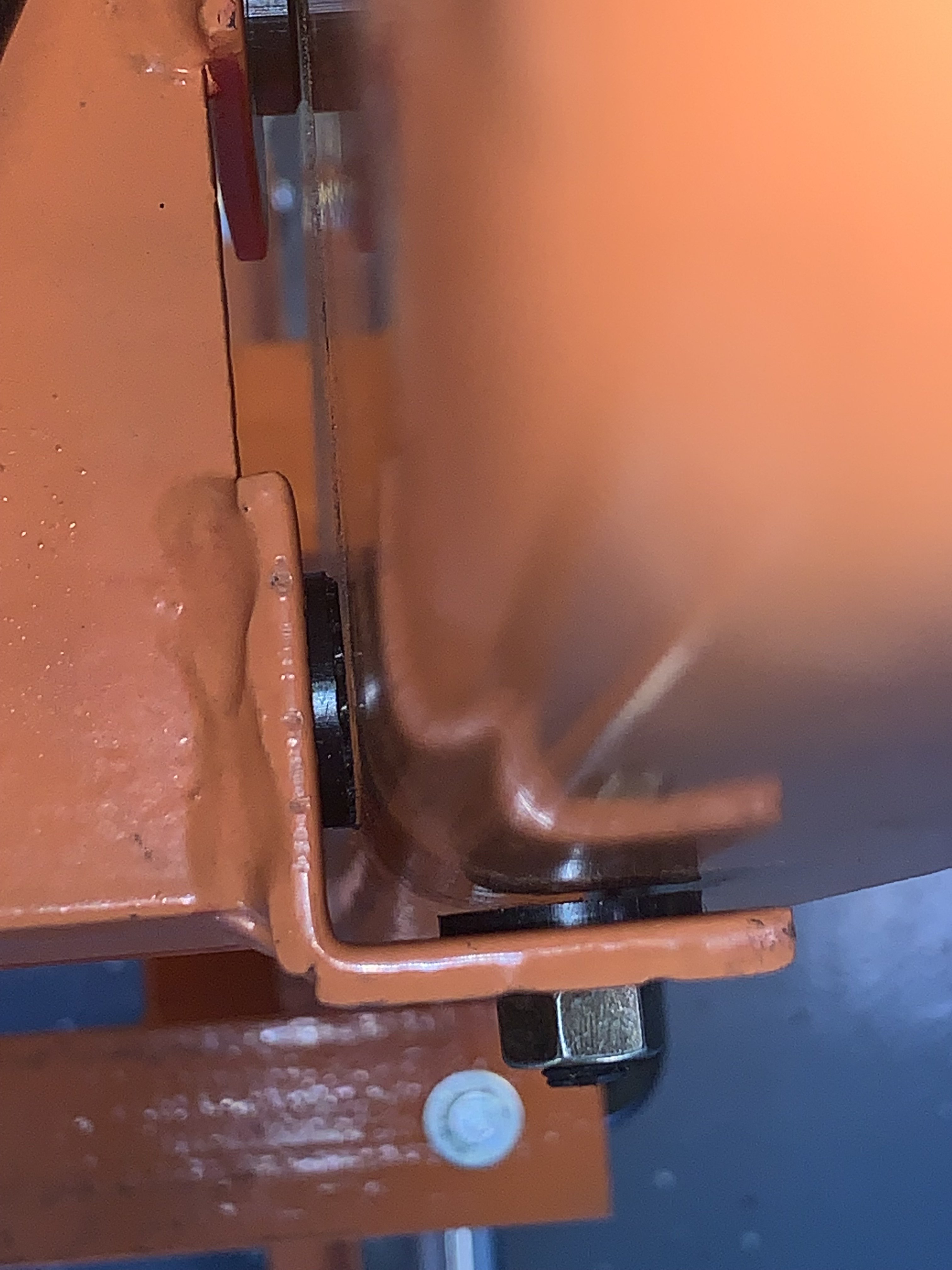

Welded over the cuts. I bolted it to the mill table and took about .005 off the end of the ram to square it up. Painted up the weld area:

Turned down and threaded some 7/8" delrin to make bushings, 4 on each side to stabilize movement of the ram.

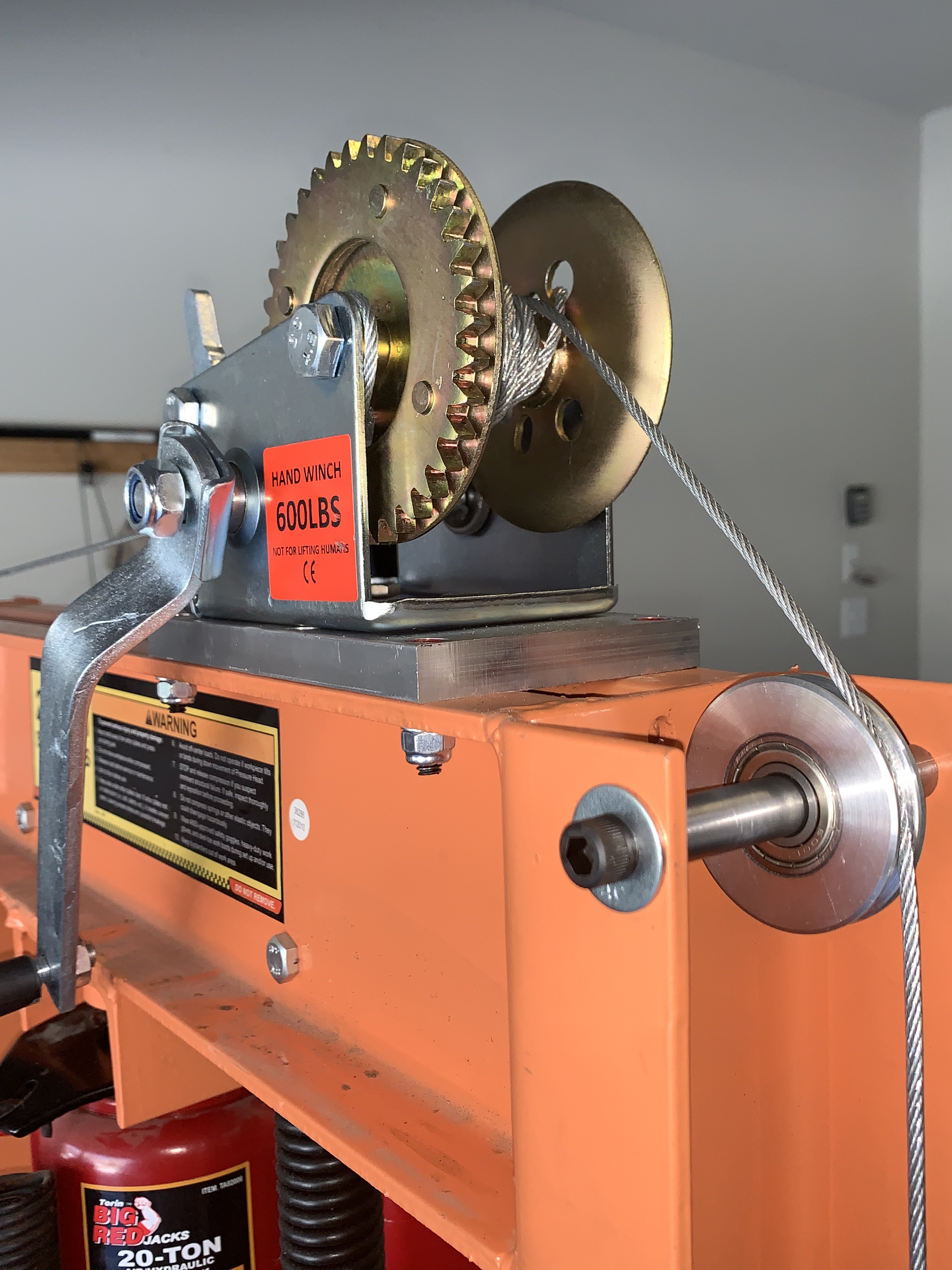

Put a small winch on top to raise and lower the table. Added hairpins to the round bars with caps. This way I can raise / lower from the front. I made the pulleys from some 2.5" al and pressed in some tired bearings I replaced out of a drill press.

Added a knob to the jack release and put wheels on it. The ram sits pretty true over the table now:

I dont have a good idea yet for the air hose, not sure I want a foot pedal. I am planning an expanded metal tray for it next that will ride in the two bottom holes. A place to store rams, dies and punches.

I thought I would take a stab at upgrading the old press. The goal was to not weaken the high stress points of the press with heat or holes.

First off was straighten the ram. I cut the welds that add stability. I used the slitting saw on the mill because it removes such a small amount of metal.

Then pounded on the ram with a sledge and a block of wood to find straight:

Welded over the cuts. I bolted it to the mill table and took about .005 off the end of the ram to square it up. Painted up the weld area:

Turned down and threaded some 7/8" delrin to make bushings, 4 on each side to stabilize movement of the ram.

Put a small winch on top to raise and lower the table. Added hairpins to the round bars with caps. This way I can raise / lower from the front. I made the pulleys from some 2.5" al and pressed in some tired bearings I replaced out of a drill press.

Added a knob to the jack release and put wheels on it. The ram sits pretty true over the table now:

I dont have a good idea yet for the air hose, not sure I want a foot pedal. I am planning an expanded metal tray for it next that will ride in the two bottom holes. A place to store rams, dies and punches.