-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Index mill, possibly a 40

- Thread starter tk1971

- Start date

- Joined

- Aug 1, 2022

- Messages

- 137

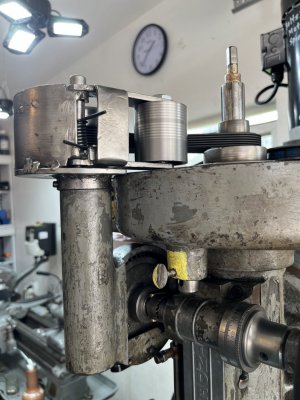

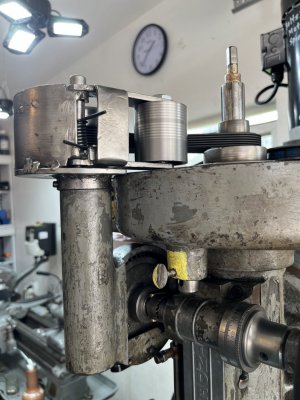

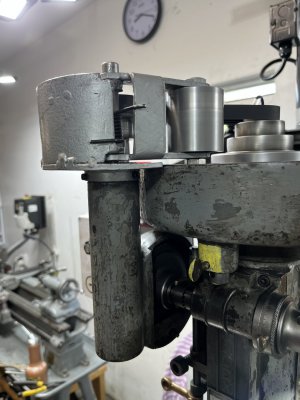

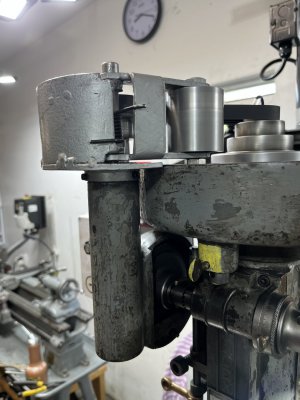

Done with the auto downfeed parts. Function verified. Up next is to smooth out any rough surfaces and paint it.

Here are the pics:

View attachment IMG_2930.MOV

Here are the pics:

View attachment IMG_2930.MOV

- Joined

- Aug 1, 2022

- Messages

- 137

Used whatever used 5 year old spray paint I had laying around to paint the downfeed parts. It’s gloppy and not well mixed but it actually fits the looks of the old mill.

As a finishing touch, I made a thumbscrew for the downfeed stop, which was only a screw when I got the mill. The 3/8” shoulder on the thumbscrew engages the downfeed stop mechanism to disengage the downfeed gears.

All that’s left is the disassembly/cleaning/re-assembly of the saddle and table, which will have to happen later.

Here are a few pics:

As a finishing touch, I made a thumbscrew for the downfeed stop, which was only a screw when I got the mill. The 3/8” shoulder on the thumbscrew engages the downfeed stop mechanism to disengage the downfeed gears.

All that’s left is the disassembly/cleaning/re-assembly of the saddle and table, which will have to happen later.

Here are a few pics:

- Joined

- Aug 1, 2022

- Messages

- 137

There was a chip on the insert that I hadn’t noticed until it was done and I was going a little fast. I’m going for function so I lightly went over it with emory paper snd called it a day. Works well stopping the downfeed and I don’t need a tool to set the position any more.Good job.

looks like the thread finished is rough. I never threaded with carbide insert , is this common with carbide? I was thinking of buying a carbide insert holder before.

The same insert was used on the roller going really slow prior to chipping? Beautiful finish there.

Ok good.

I'm sorry if I came off as being a critic, just wondering if that was normal for inserts. Now I know it’s not, I may invest in a threading insert. i have always used high speed ground by hand. Which at best is not perfect.

do you recommend a insert and tool holder.

I'm sorry if I came off as being a critic, just wondering if that was normal for inserts. Now I know it’s not, I may invest in a threading insert. i have always used high speed ground by hand. Which at best is not perfect.

do you recommend a insert and tool holder.

- Joined

- Aug 1, 2022

- Messages

- 137

Nah, I like criticism (beginner here) and I didn’t take it as such.Ok good.

I'm sorry if I came off as being a critic, just wondering if that was normal for inserts. Now I know it’s not, I may invest in a threading insert. i have always used high speed ground by hand. Which at best is not perfect.

do you recommend a insert and tool holder.

Any of the import threading bars are all the same IMO. I do have to say that the cheap inserts are a gamble. I had 4 out of 10 get dull faster than they should. I suppose good USA made inserts would work on import bars just fine.

For me (a rank amateur) I started with the cheap stuff so I could get a feel for what I wanted to replace with “real” tools. Plus, I wouldn’t feel bad about breaking stuff when figuring out the limitations of my lathe/mill.

Just picked up one of these model 40’s at a local online auction (Kansas City area). It has the same z collet chuck on b&s #9 taper. I was finally able knock mine loose with the draw bar and a heavy brass hammer. I am glad I didn’t read your ordeal before hand or I might have been much more worried about getting it out. I also have a Rusnok model 80 and quickly came to the conclusion I needed a larger working envelope for some of the things I wanted to do. I had been looking at horizontal mills to put the Rusnok head on when I came access this Index mill. The 1250 pounds is about the biggest thing I can handle and get into my shop. Hope to see a lot more of your posts on the rebuild of this mill. I am new to machining but have been a metalsmith for over 40 years. Started down this road mainly to make tooling for my smithing machinery and quickly fell in love the processes.

- Joined

- Aug 6, 2015

- Messages

- 4,166

Welcome to the forum!!!Just picked up one of these model 40’s at a local online auction (Kansas City area). It has the same z collet chuck on b&s #9 taper. I was finally able knock mine loose with the draw bar and a heavy brass hammer. I am glad I didn’t read your ordeal before hand or I might have been much more worried about getting it out. I also have a Rusnok model 80 and quickly came to the conclusion I needed a larger working envelope for some of the things I wanted to do. I had been looking at horizontal mills to put the Rusnok head on when I came access this Index mill. The 1250 pounds is about the biggest thing I can handle and get into my shop. Hope to see a lot more of your posts on the rebuild of this mill. I am new to machining but have been a metalsmith for over 40 years. Started down this road mainly to make tooling for my smithing machinery and quickly fell in love the processes.