- Joined

- Aug 1, 2022

- Messages

- 137

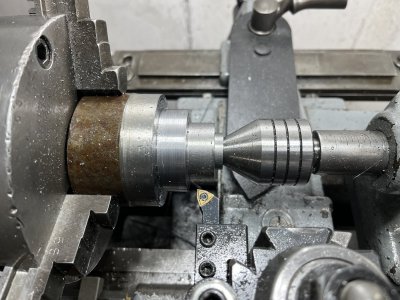

Re-installed the spindle.

Had a motor laying around but it needed some mods to work. Turned down the rest of the shaft to 3/4” on the lathe (only about 1.5” at the tip was 3/4” diameter with key ), then extended the 3/16” keyway on another mill. Also welded a mount to the motor body.

installed new bearings on that middle pulley shaft, keeping the spindle pulley and the bottom middle pulley that mates with it using a new Gates 2346 (4L346) belt.

For the motor pulley I’m using a new 6” pulley, mating it with a 3.95” pulley for the top middle pulley using a new 4L300 belt. With the spindle and lower middle pulleys both at 6”, this will max out at about 2600 RPM. Had to put both the new motor and upper middle pulleys on the lathe to get them to line up properly, given how long the motor shaft is (should have turned more of the shaft down to 3/4”). With all that done, both belts snug up well at the first “click” of the belt tensioning mechanism.

Reassembled the down feed with new bearings and a new taper pin, which had to be cut to make it flush.

I’m going to try and make the upper down feed housing, stepped flat pulley and idler roller assembly when everything is done.

Started laying out the vfd controls along with tach on a box that will be mount on the mill. Also need to wire up breakers / vfd into a box and the x-axis feed motor.

Almost there… here are sone pics.

Had a motor laying around but it needed some mods to work. Turned down the rest of the shaft to 3/4” on the lathe (only about 1.5” at the tip was 3/4” diameter with key ), then extended the 3/16” keyway on another mill. Also welded a mount to the motor body.

installed new bearings on that middle pulley shaft, keeping the spindle pulley and the bottom middle pulley that mates with it using a new Gates 2346 (4L346) belt.

For the motor pulley I’m using a new 6” pulley, mating it with a 3.95” pulley for the top middle pulley using a new 4L300 belt. With the spindle and lower middle pulleys both at 6”, this will max out at about 2600 RPM. Had to put both the new motor and upper middle pulleys on the lathe to get them to line up properly, given how long the motor shaft is (should have turned more of the shaft down to 3/4”). With all that done, both belts snug up well at the first “click” of the belt tensioning mechanism.

Reassembled the down feed with new bearings and a new taper pin, which had to be cut to make it flush.

I’m going to try and make the upper down feed housing, stepped flat pulley and idler roller assembly when everything is done.

Started laying out the vfd controls along with tach on a box that will be mount on the mill. Also need to wire up breakers / vfd into a box and the x-axis feed motor.

Almost there… here are sone pics.

Attachments

-

E95F1037-C507-45E3-8931-A70AC8ADFA0D.jpeg369.7 KB · Views: 4

E95F1037-C507-45E3-8931-A70AC8ADFA0D.jpeg369.7 KB · Views: 4 -

EE63D009-21FB-4433-BCB6-38A828496913.jpeg657.1 KB · Views: 5

EE63D009-21FB-4433-BCB6-38A828496913.jpeg657.1 KB · Views: 5 -

7D80FAD4-C271-4C6A-8D06-9B7309F134C3.jpeg311.4 KB · Views: 5

7D80FAD4-C271-4C6A-8D06-9B7309F134C3.jpeg311.4 KB · Views: 5 -

FA7D6745-D3EB-4D0A-AE74-F9B9C300FCC5.jpeg175.8 KB · Views: 4

FA7D6745-D3EB-4D0A-AE74-F9B9C300FCC5.jpeg175.8 KB · Views: 4 -

2088A3B7-8316-4B5E-B7D4-06F0D521944C.jpeg265.7 KB · Views: 3

2088A3B7-8316-4B5E-B7D4-06F0D521944C.jpeg265.7 KB · Views: 3