- Joined

- Jan 29, 2014

- Messages

- 156

I am looking for a good drill chuck for my mill. I have purchased several on eBay but am less than impressed with the runout.

What should my expectations be?

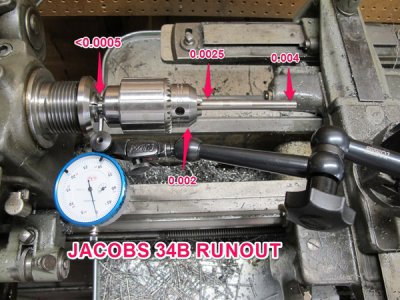

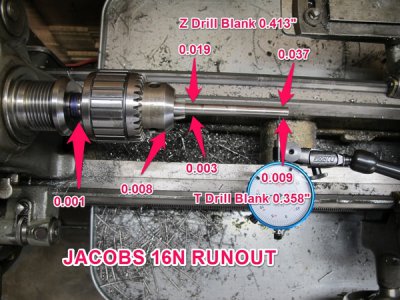

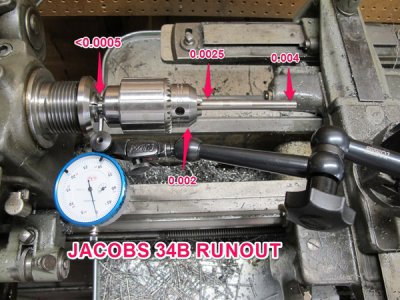

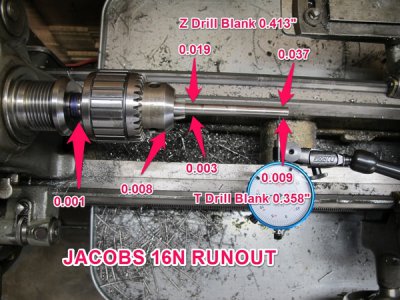

Here is the runout on three of the chucks I have collected.

When I put the Z drill blank into a collet I get less than 0.0005" runout near the collet and at the end of the blank. So I believe the drill blank is not bent nor is there an alignment problem with the lathe.

I am pretty happy with the 34B. I got is for less than $25 on eBay. But I thought the ball bearing N series of chucks was supposed to be much better. (And I certainly paid much more for them.)

The arbor the 16N is mounted on is one I just turned on the lathe. I know it is not bent or abused.

None of these chucks seem abused, the jaws and body do not show any marks.

What should I expect from a good quality drill chuck?

What should my expectations be?

Here is the runout on three of the chucks I have collected.

When I put the Z drill blank into a collet I get less than 0.0005" runout near the collet and at the end of the blank. So I believe the drill blank is not bent nor is there an alignment problem with the lathe.

I am pretty happy with the 34B. I got is for less than $25 on eBay. But I thought the ball bearing N series of chucks was supposed to be much better. (And I certainly paid much more for them.)

The arbor the 16N is mounted on is one I just turned on the lathe. I know it is not bent or abused.

None of these chucks seem abused, the jaws and body do not show any marks.

What should I expect from a good quality drill chuck?