- Joined

- Nov 5, 2016

- Messages

- 1,419

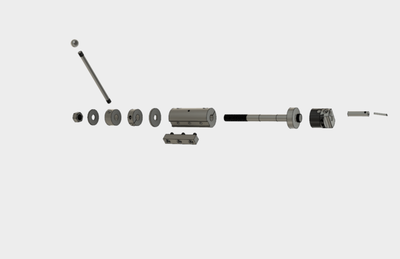

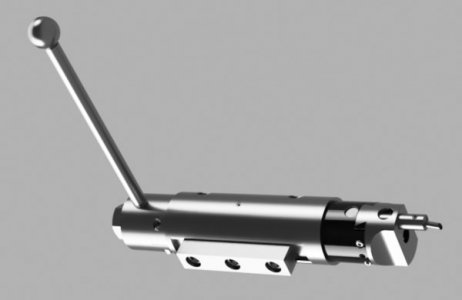

Drew it up in Fusion 360 first. I love this program especially for designing assemblies like this! I over built it, but it's as rugged as a tank and very solid. No vibration or chatter at all. Nothing special internal wise; no bronze bushings or bearings. Just a steel reamed bore with a steel spindle. I added an oil hole in the main body and I'm sure for the limited speed/rotation it will last forever. I split the main body and added clamping screws so I could tighten the bore up if needed to prevent chatter, but it worked fine just having them slightly snug with no drag on the spindle.

The round HSS tool bit gave an utterly fantastic finish! The pictures of the ball in the lathe are

just as finish turning with no polishing at all at that point. I did polish it some before installing it on the handle. There is a picture of this, but it doesn't show up well.

just as finish turning with no polishing at all at that point. I did polish it some before installing it on the handle. There is a picture of this, but it doesn't show up well.

It was a fun little project using only material I had on hand. Now, I going to have to look around and see what else I can make some balls for!

Ted

The round HSS tool bit gave an utterly fantastic finish! The pictures of the ball in the lathe are

just as finish turning with no polishing at all at that point. I did polish it some before installing it on the handle. There is a picture of this, but it doesn't show up well.

just as finish turning with no polishing at all at that point. I did polish it some before installing it on the handle. There is a picture of this, but it doesn't show up well. It was a fun little project using only material I had on hand. Now, I going to have to look around and see what else I can make some balls for!

Ted