- Joined

- Oct 16, 2019

- Messages

- 6,848

I got bit by the laser bug in the Fall and bought a 10w output Ortur diode laser. I like it but it's not powerful enough.

My shop is very limited in floor space so I needed more power in a compact footprint.

The smallest 50w CO2 laser is still 41" long by 27" deep, has a working are of 12" x 20". And it's a whopping $2700CDN.

So I looked at scratch building one and that was going to be as expensive albeit it would give me a larger working area.

While making sure I used as much of my monthly internet bandwidth I happened upon a blog where the writer had modified a K40 laser to create a 12x24" working area. These machines have a much smaller foot print, usually 27" to 30" L by 20" or so deep.

replicantfx.com

replicantfx.com

These machines out of the box are not exactly high quality but there is a huge community of folks who use them in stock or modified form. The first and most common upgrade is to swap the control board for one that will run GRBL and Lightburn which is the defacto standard for laser control software.

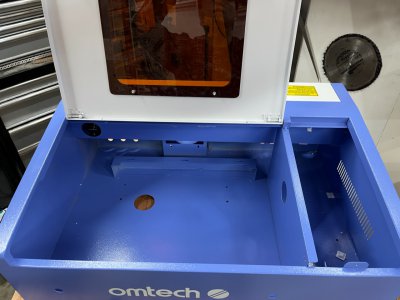

So I took the plunge and bought an OmTech K40 via eBay for $445 CDN

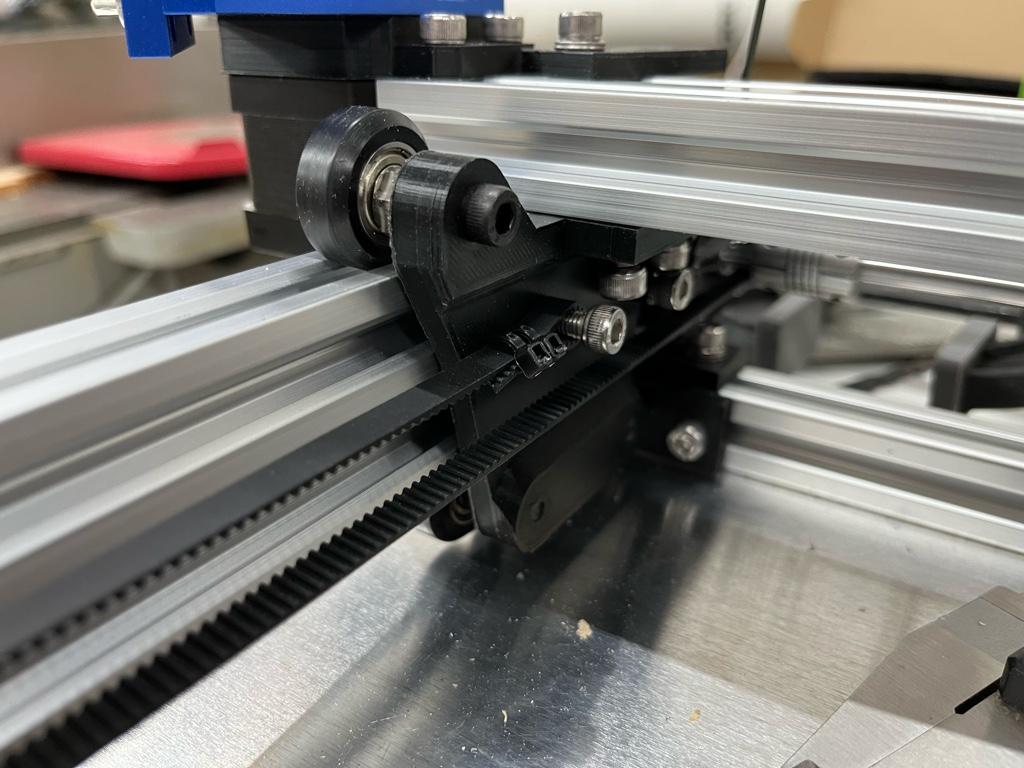

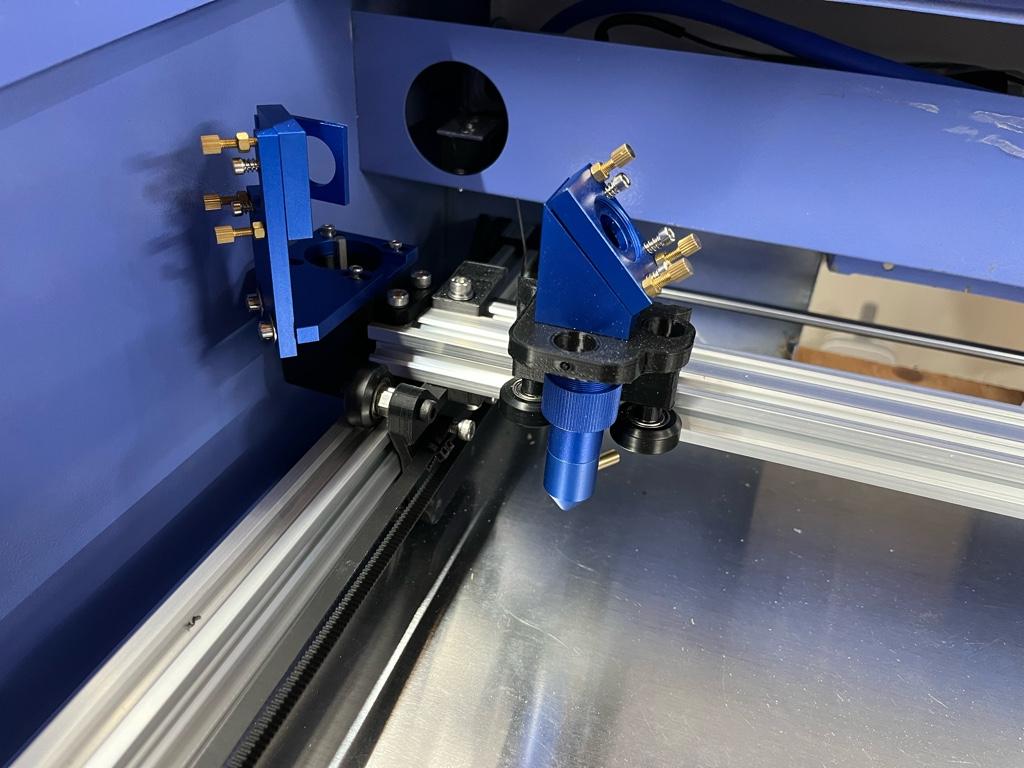

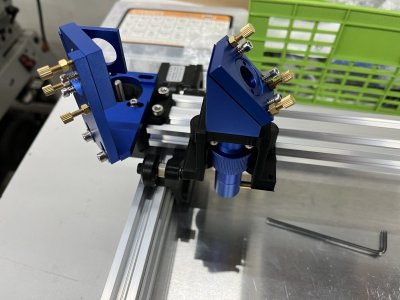

Bought a GRBL control board from VMS and a bunch of bit and bobs including some 2020 and 2040 extrusion for the gantry.

Fired up the 3D printer and printed off all the necessary pieces.

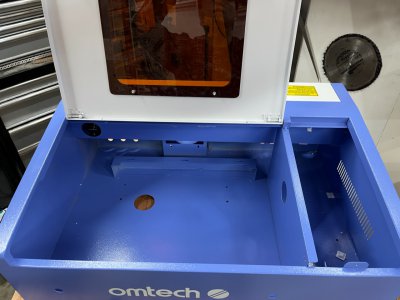

Stripped out all of the original works in preparation for the new gantry.

(I neglected to take a pic of the original gantry and electronics...)

The gantry was on the left side of the divider and power supply, control board and what not were on the right side.

I'm covering the bottom with a piece of 1/2" plywood with 24ga aluminum glued to it..

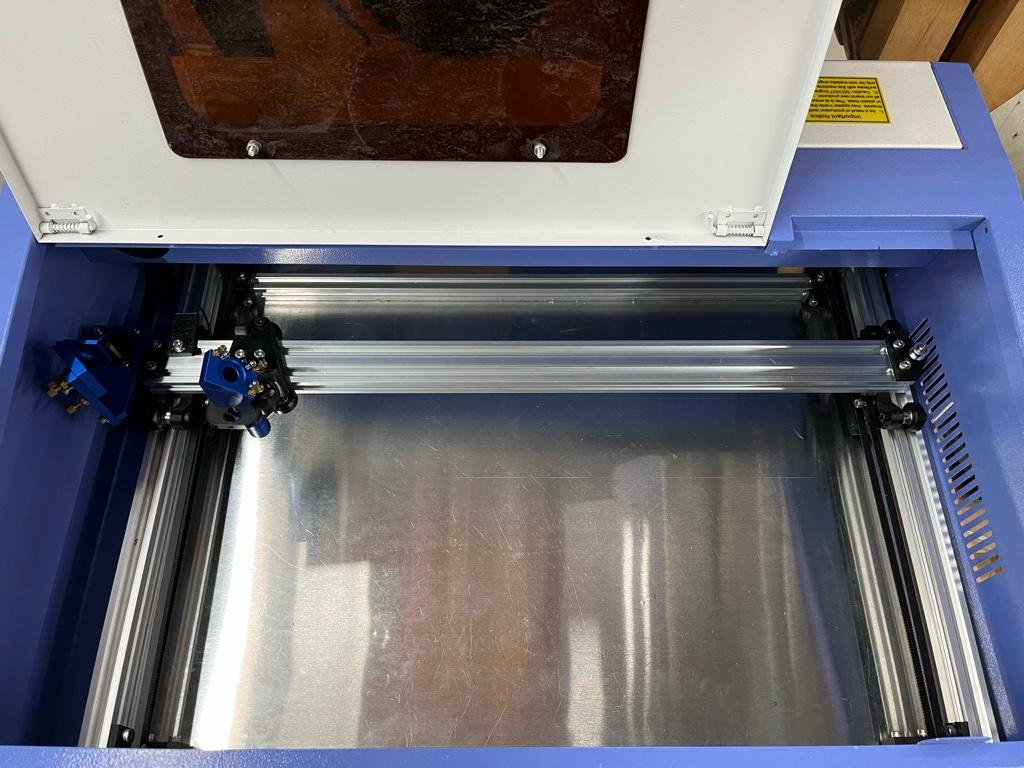

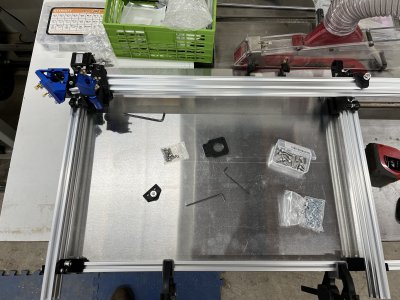

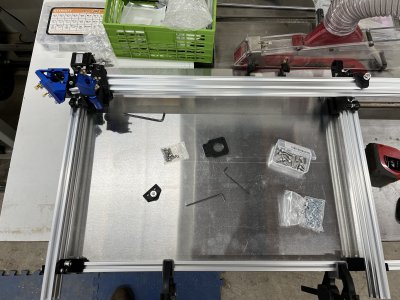

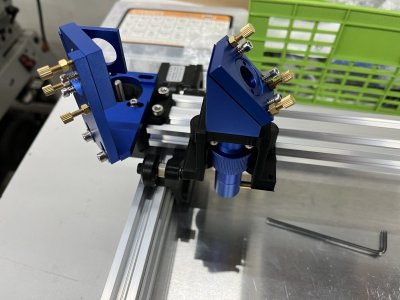

Here’s the basic build of the gantry.

The opening of the enclosure is 25.5”w while the floor of the laser enclosure is 27.75 wide by 19.5” deep

Measuring 27.5” from the left side motor mount to the right hand end of the gantry will yield 20.75” of travel in the X axis.

I should net about 12.5” of travel in the Y axis.

All in I should be able to complete this build for about $800 - $900 or about $1900 less than a new machine.

My shop is very limited in floor space so I needed more power in a compact footprint.

The smallest 50w CO2 laser is still 41" long by 27" deep, has a working are of 12" x 20". And it's a whopping $2700CDN.

So I looked at scratch building one and that was going to be as expensive albeit it would give me a larger working area.

While making sure I used as much of my monthly internet bandwidth I happened upon a blog where the writer had modified a K40 laser to create a 12x24" working area. These machines have a much smaller foot print, usually 27" to 30" L by 20" or so deep.

K40 Laser Cutter Rebuild (12x24in) – Arroway Ltd.

These machines out of the box are not exactly high quality but there is a huge community of folks who use them in stock or modified form. The first and most common upgrade is to swap the control board for one that will run GRBL and Lightburn which is the defacto standard for laser control software.

So I took the plunge and bought an OmTech K40 via eBay for $445 CDN

Bought a GRBL control board from VMS and a bunch of bit and bobs including some 2020 and 2040 extrusion for the gantry.

Fired up the 3D printer and printed off all the necessary pieces.

Stripped out all of the original works in preparation for the new gantry.

(I neglected to take a pic of the original gantry and electronics...)

The gantry was on the left side of the divider and power supply, control board and what not were on the right side.

I'm covering the bottom with a piece of 1/2" plywood with 24ga aluminum glued to it..

Here’s the basic build of the gantry.

The opening of the enclosure is 25.5”w while the floor of the laser enclosure is 27.75 wide by 19.5” deep

Measuring 27.5” from the left side motor mount to the right hand end of the gantry will yield 20.75” of travel in the X axis.

I should net about 12.5” of travel in the Y axis.

All in I should be able to complete this build for about $800 - $900 or about $1900 less than a new machine.