- Joined

- Apr 24, 2022

- Messages

- 76

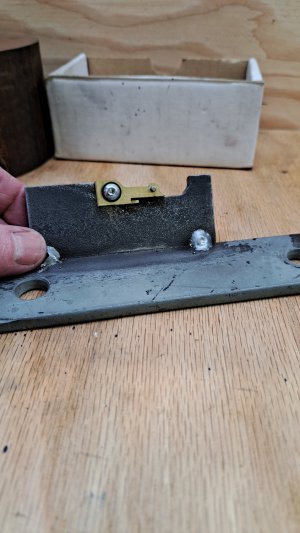

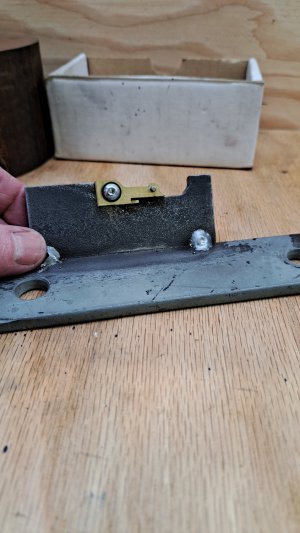

I had an operation I needed to perform using a carbide burr. I had a jig setup to shape the profiles of some brass parts using the burr. I absent-mindedly mounted the carbide burr in a keyless 1/2 drill chuck, not thinking about how I was going to be side-loading the tool for this operation. Stupid me, should've had the burr mounted in a collet or mill holder instead. Only upon finishing the operation and going to remove the burr did I realize my bone headed mistake and figured I'd ruined the chuck. Went to drill a very small (#56) hole and sure enough that drill bit danced around like a hula girl. Ordered a new chuck. Hopefully I can take the buggered one apart and make it serviceable again. Lesson learned - keyless drill chucks are for drilling, not milling or other side-loading of tooling.