Every now and then, I need to turn a taper, but I am not blessed to have a taper attachment on my lathe and the prices they sell for are more than I paid for my lathe, the bench and the tooling. I cannot justify the cost. Soooooo....... as usual , I MADE MY OWN.

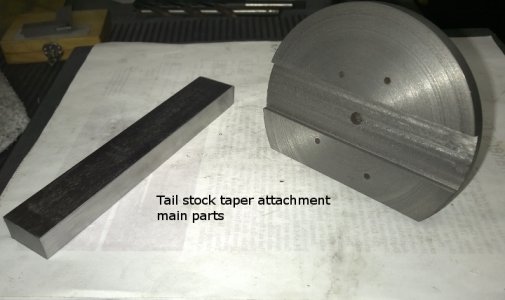

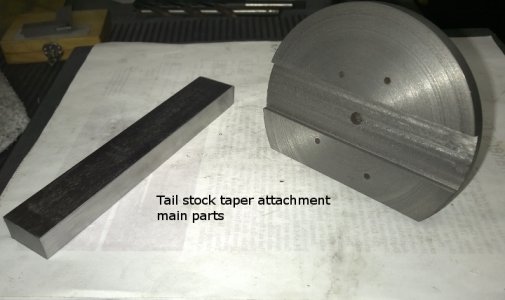

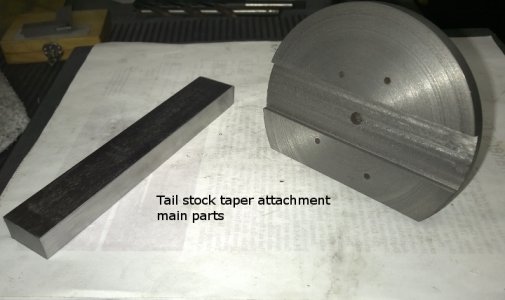

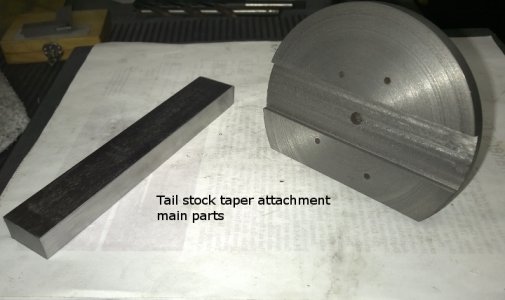

I had an old cast iron drill pad that I never used , so with a little machining I built the taper attachment that I found in some old vintage magazine article. I don't know who came up with it , but it is a nice design. It fits in the tail stock and you can adjust the center offset for most common tapers. I make a lot of Morse tapers since I make most of my tooling and this will make that easier. Check it out and you may like to make this for yourself.

This was an old cast iron drill pad. The taper was off, so I cut a new no 2 Morse taper on the back end.

This was an old cast iron drill pad. The taper was off, so I cut a new no 2 Morse taper on the back end.

I then milled a slot to hold a 1" x 1/2" x 5 1/4" steel bar.

I then milled a slot to hold a 1" x 1/2" x 5 1/4" steel bar.

This was my mill setup for machining the slot.

This was my mill setup for machining the slot.

I cut the slot with a 3/4" end mill and widened it for a snug sliding fit on the bar.

I cut the slot with a 3/4" end mill and widened it for a snug sliding fit on the bar.

Test fit in the tail stock

Test fit in the tail stock

I machined two 3/8" slots on each side of a drilled and reamed a 1/2" hole.

I machined two 3/8" slots on each side of a drilled and reamed a 1/2" hole.

The hole holds a center made from drill rod and is a light press fit in the 1/2" hole. two 3/8-16 bolts clamp the bar to the pad through the slots. The flat cut on the top of the pad is to set a level on so the attachment is level with the lathe bed when you put it in the tail stock.

The hole holds a center made from drill rod and is a light press fit in the 1/2" hole. two 3/8-16 bolts clamp the bar to the pad through the slots. The flat cut on the top of the pad is to set a level on so the attachment is level with the lathe bed when you put it in the tail stock.

An easy to build tool that comes in handy and no more offsetting the tail stock after I got it all trued up.

By the way, since I had the drill pad , this attachment cost me nothing to make. Got the bar from my scrap box and had the bolts lying around, and the center was a short scrap of 5/8 drill rod.

Mark Frazier

I had an old cast iron drill pad that I never used , so with a little machining I built the taper attachment that I found in some old vintage magazine article. I don't know who came up with it , but it is a nice design. It fits in the tail stock and you can adjust the center offset for most common tapers. I make a lot of Morse tapers since I make most of my tooling and this will make that easier. Check it out and you may like to make this for yourself.

This was an old cast iron drill pad. The taper was off, so I cut a new no 2 Morse taper on the back end.

This was an old cast iron drill pad. The taper was off, so I cut a new no 2 Morse taper on the back end.

I then milled a slot to hold a 1" x 1/2" x 5 1/4" steel bar.

I then milled a slot to hold a 1" x 1/2" x 5 1/4" steel bar. This was my mill setup for machining the slot.

This was my mill setup for machining the slot. I cut the slot with a 3/4" end mill and widened it for a snug sliding fit on the bar.

I cut the slot with a 3/4" end mill and widened it for a snug sliding fit on the bar. Test fit in the tail stock

Test fit in the tail stock I machined two 3/8" slots on each side of a drilled and reamed a 1/2" hole.

I machined two 3/8" slots on each side of a drilled and reamed a 1/2" hole. The hole holds a center made from drill rod and is a light press fit in the 1/2" hole. two 3/8-16 bolts clamp the bar to the pad through the slots. The flat cut on the top of the pad is to set a level on so the attachment is level with the lathe bed when you put it in the tail stock.

The hole holds a center made from drill rod and is a light press fit in the 1/2" hole. two 3/8-16 bolts clamp the bar to the pad through the slots. The flat cut on the top of the pad is to set a level on so the attachment is level with the lathe bed when you put it in the tail stock. An easy to build tool that comes in handy and no more offsetting the tail stock after I got it all trued up.

By the way, since I had the drill pad , this attachment cost me nothing to make. Got the bar from my scrap box and had the bolts lying around, and the center was a short scrap of 5/8 drill rod.

Mark Frazier

Last edited by a moderator: