- Joined

- Sep 20, 2012

- Messages

- 560

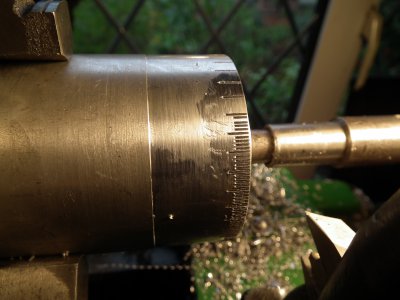

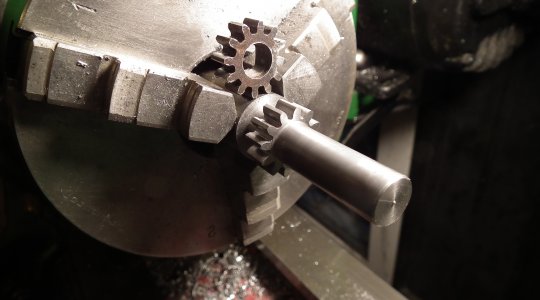

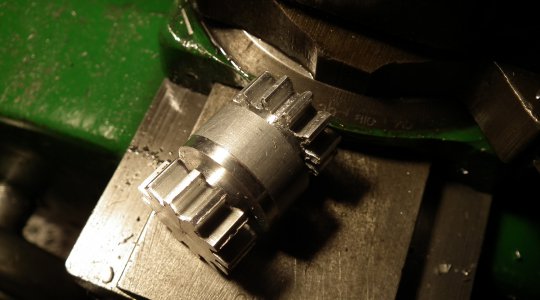

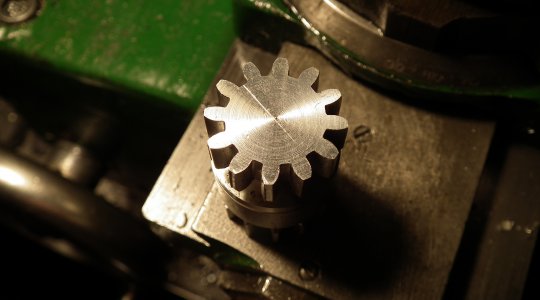

I was thinking about making an attachment for broaching key-ways and similar jobs, and it occurred to me that a lever operated compound fitted with a QCTP could be quite useful, I had a spare compound assembly so this is what I ended up with.

The leverage worked out about right, it's effortless to use and seems to work OK so far, I'm thinking that with a number of tool holders set up it might even work like a capstan..

Bernard

The leverage worked out about right, it's effortless to use and seems to work OK so far, I'm thinking that with a number of tool holders set up it might even work like a capstan..

Bernard

Last edited: