- Joined

- Dec 6, 2012

- Messages

- 2,677

I'm likely starring at the solution. However, I can't see it.

I'm cutting a bevel gear. I intend to post the adventure here at HM later when all is complete.

Regardless, I'm trying to figure out the easiest most accurate way to set up the mill.

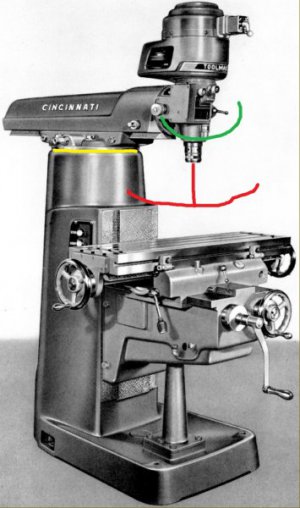

Specifically, please note the Cincy pic.

The machine swivels at the column (yellow).

This creates a larger arc (red).

Usually this is not an issue because 90degrees meets the table and it doesn't matter if the ram is 90degrees to the column or off by 30degrees.

However, for a mill cut bevel the head needs to swivel (green).

If the ram isn't at 90degress everything goes wonky.

I took a couple hours to figure out why my first attempt at the gear went to scrap.

How do I most accurately and easily adjust the ram to 90degrees to the column.

All I'm coming up with is when a quill or ram mounted indicator is at the shortest arc I'm at 90degrees.

However, that assumes that the indicator is at 90degrees to the ram.

This is like a rebuilding question, I should really go back to Connely and my fingers are oily.

Likely late tonight if I don't hear from somebody here at HM...

Thanks!!

Daryl

MN

.

.

I'm cutting a bevel gear. I intend to post the adventure here at HM later when all is complete.

Regardless, I'm trying to figure out the easiest most accurate way to set up the mill.

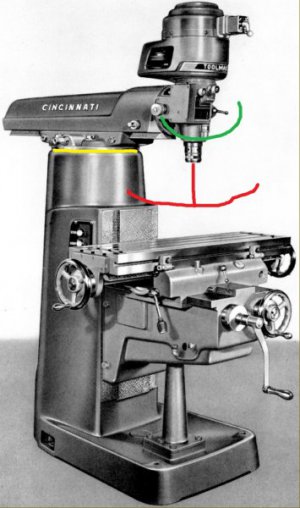

Specifically, please note the Cincy pic.

The machine swivels at the column (yellow).

This creates a larger arc (red).

Usually this is not an issue because 90degrees meets the table and it doesn't matter if the ram is 90degrees to the column or off by 30degrees.

However, for a mill cut bevel the head needs to swivel (green).

If the ram isn't at 90degress everything goes wonky.

I took a couple hours to figure out why my first attempt at the gear went to scrap.

How do I most accurately and easily adjust the ram to 90degrees to the column.

All I'm coming up with is when a quill or ram mounted indicator is at the shortest arc I'm at 90degrees.

However, that assumes that the indicator is at 90degrees to the ram.

This is like a rebuilding question, I should really go back to Connely and my fingers are oily.

Likely late tonight if I don't hear from somebody here at HM...

Thanks!!

Daryl

MN

.

.

Last edited: