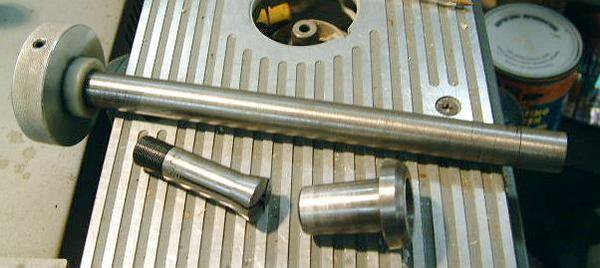

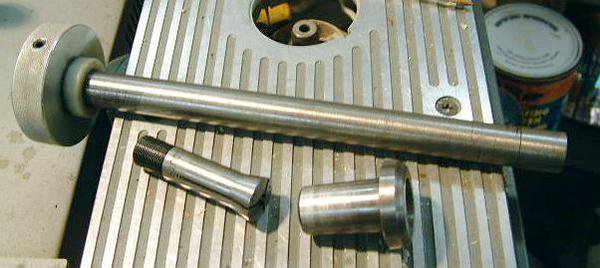

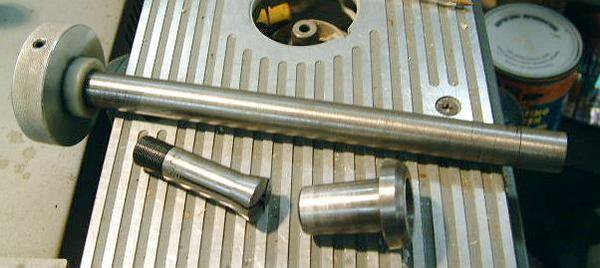

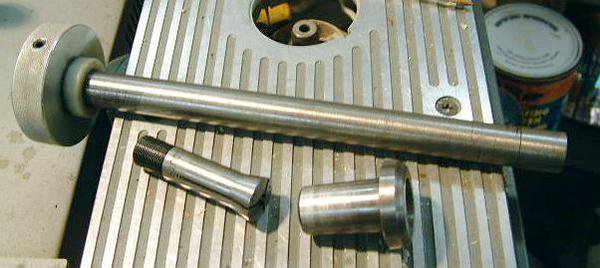

This is a shop-made drawbar for a 10" Atlas lathe for 3C collets. I used it for about 15 years.

The drawbar itself is 1/2" pipe. The white piece is a thrust bearing made from some synthetic material.. about anything would do. Nylon or delrin for example. Even HDPE or LDPE. I had to open the gear cover door and leave it open when I used the 3C drawbar. You could bore out the gear cover and make a long spacer so the handwheel is outside the gear cover. I took the easy way and just opened the gear cover.

The knurled aluminum handle is 2 7/8" diameter and held to the drawbar with setscrews.

The threaded end of the drawbar was done separately and silver soldered onto the 1/2" pipe. Come to think of it the threaded part was silver soldered onto the drawbar and then it was threaded so as to be concentric with the drawbar. The threaded part is the most difficult, if you want to call it that.

I had all South Bend 3C collets because I found them in a used machinery store and snapped them up. They were very inexpensive despite being new-in-box. There's not a lot of industry use for 3C collets.

Where else but ebay?

http://shop.ebay.com/i.html?_from=R..._nkw=3c+collets&_sacat=See-All-Categories

I wouldn't spend the money for South Bend or Hardinge collets. The Chinese are plenty good and very inexpensive.

Discount Machine is Shars on ebay. $9.55 each.

http://cgi.ebay.com/1-16-1-2-3C-ROU...=BI_Tool_Work_Holding&hash=item5194a53c04

If you have a 7x or 9x lathe and have never used collets you're in for a treat. In addition to round you can find hex in 3C and I think square up to a certain size. 3C range from 1/8" to 1/2". I don't know if there are smaller than 1/8".

You can also adapt watch maker collets if you need ittsy bitsy collets.

3AT collets are almost the same dimensionally as 3C, as I recall. From memory I seem to remember the length was the major difference. I would concentrate on 3C unless you can snag a set of 3AT cheap.

$25 for the 3C/3MT collet adaptor. They also have drawbars but why spend $140 when you can make one just as good for next to nothing? It's an easy piece of tooling to make.

http://www.tools4cheap.net/products.php?cat=22

As I recall I hand-filed the pipe OD to smooth it out and insure there was nothing to impede function.