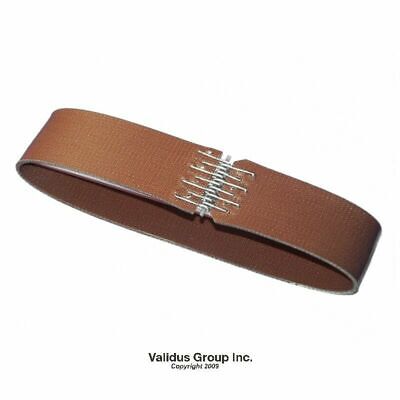

I recently acquired another SB9a, with a flat belt drive (other 9a has v belt pulleys). I want to replace the flat belt with another leather belt. With the lathe came a piece of leather the correct length for the pulleys, but not the correct width. The width is 1.5" and I want to make it almost 1". It is approximately .1875" thick. 2 questions.

1. What is the best tool to cut the along the length of the belt?

2. What would be a good substitute for the gut material used to stitch it together, in case I have difficulty locating some?

1. What is the best tool to cut the along the length of the belt?

2. What would be a good substitute for the gut material used to stitch it together, in case I have difficulty locating some?