- Joined

- Jan 22, 2014

- Messages

- 578

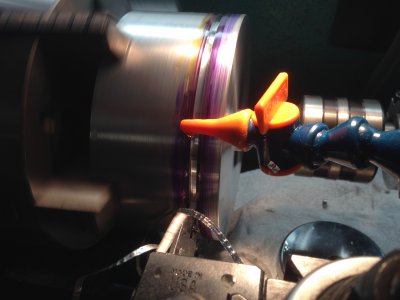

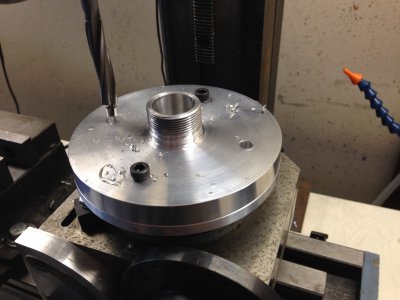

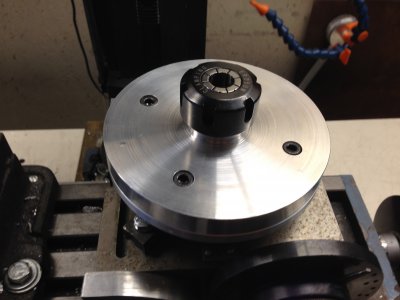

About a year ago I bought a mini 4-Jaw chuck (UniMat 2 ½”/ 65mm) for a for a Tailstock Off-Center Tapering jig using an M3 mount. I can also mount it in the spindle with an M3/M4 adapter. The other day I was working on another project where I wished I could also use it in my rotary table so I made a simple adapter plate. Not only did this give me more versatility now having 4-Jaw, but it’s also has a much lower profile than my 4” 3-Jaw that I bought with the RT. Once it was mounted to the adapter plate, I found that I needed to throw the part back in the lathe and I could do this w/o dismounting the part using the adapter plate and running perfectly true.

I love it when I get to use a tool or fixture for more than the intended purpose, maximizing both my dollar and my tooling arsenal.

I love it when I get to use a tool or fixture for more than the intended purpose, maximizing both my dollar and my tooling arsenal.

Last edited: