- Joined

- Dec 29, 2012

- Messages

- 394

20 years ago my father bought a McCulloch Eager Beaver II chainsaw to use it for branch cutting to the trees at a distance from home where electricity was unavailable.

He used the chainsaw the first season and had it in the store room for the next couple of years. When he tried to cut some thick branches three years later he could not start the engine. As the guarantee had already expired, instead of going to the dealer for repair he gave it to an “expert” friend of a friend to fix it. In the mean time he got ill and passed away within the next 6 months, so the chainsaw remained with the “expert”.

A year later my mother tried to find the chainsaw and the “expert” gave her an Eager Beaver II in a very poor condition, saying that it was beyond repair. I believe that chainsaw wasn’t my father’s chainsaw, but as there was no receipt I cannot prove anything. My mother stored it in a box and forgot about it.

Last week I found it consigned in my mother’s store room and took it to have a go with it.

I put some fresh gasoline, I pulled the rope several times, there is compression but no spark. When I researched for problems I discovered that the weak part of the chainsaws are coils that generate the spark.

The particular Eager Beaver II has a simple coil that is not working.

A search at ebay revealed that the particular coil is not available new anymore, it is hard to find and it is very expensive ($60 for a used coil).

I had to either forget all about fixing the saw or look for an alternative solution.

My first thought was to substitute it with another one from another maker. Unfortunately, every chainsaw maker designs his own coil! Some of them fit other models but none fits mine.

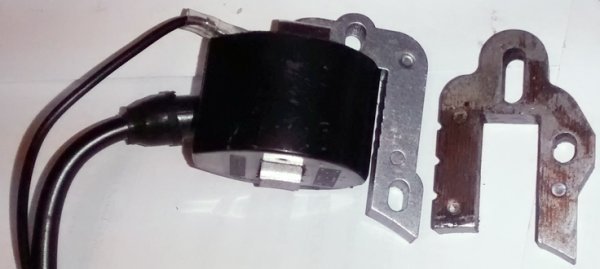

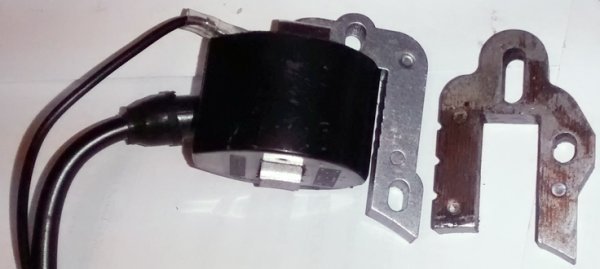

I noticed that coils consist of two separate parts: A laminate iron core and some windings encapsulated in a plastic container.

Most of the coils have similar containers but different laminated cores.

Solution is simple If I find a similar container I could change the core and have a brand new coil!!!!

I looked for a coil that has the same number of laminates with the original one.

It was easy to find it. Made for Husqvarna saws at a ridiculous cost (7.5$ including postage from Hong Kong!

I ordered it thinking that if it does not work I would have lost the equivalent cost of a six pack of beers!

Coil arrived and it looks promising.

I first removed the laminate core from the original part

Then, carefully, I removed the core from the new coil

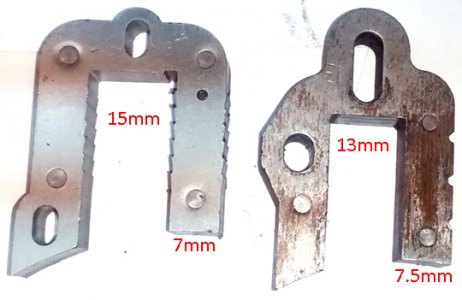

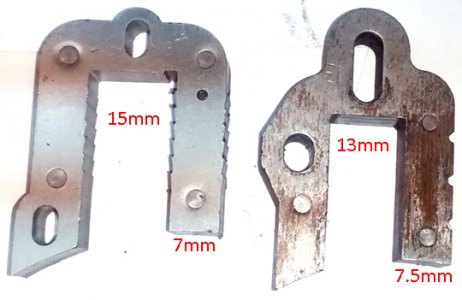

A comparison of the two revealed that although they have the same number of laminates (i.e. the same thickness) they have minor differences to other dimensions so I must do some modifications to fit the old one to the new container.

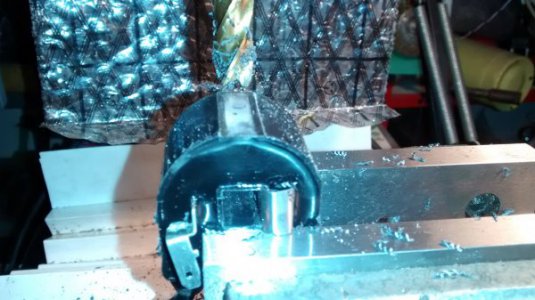

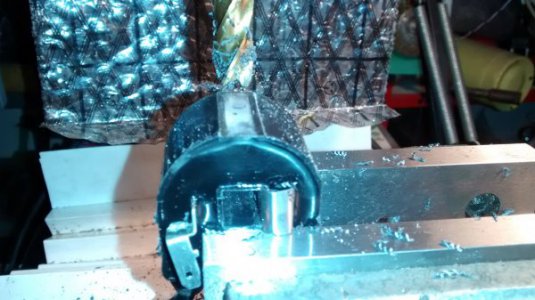

First the part of the laminate that goes in the center of the container from 7.5mm had to be made 7mm. An easy work for my mill.

Next the container needed to be1mm thinner for the external leg of the laminate. Another easy job for the mill

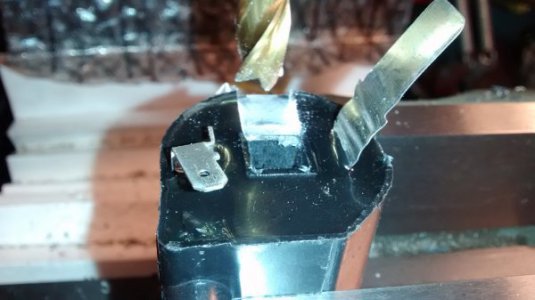

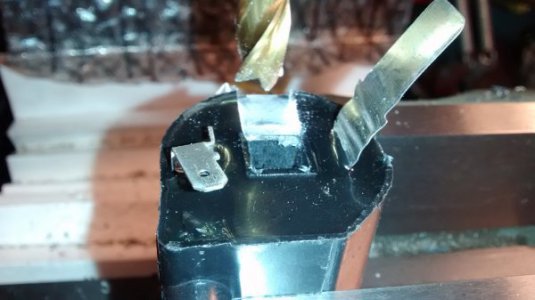

Next, as the old laminate core is 1mm shorter, the container needed to be 1mm lower for a perfect fit.

Needless to say that During all this machining there was no wiring or electronics exposed so no harm done to the electronics.

So the old laminate iron core fits perfectly to the new coil

And there is my new part according to original specs (in comparison to the original)

It fits perfectly on the motor.

And, most important! it gives spark when I rotate the engine.

It remains to fix the carburetor and Its done!!!

Thanks for reading

Petros

He used the chainsaw the first season and had it in the store room for the next couple of years. When he tried to cut some thick branches three years later he could not start the engine. As the guarantee had already expired, instead of going to the dealer for repair he gave it to an “expert” friend of a friend to fix it. In the mean time he got ill and passed away within the next 6 months, so the chainsaw remained with the “expert”.

A year later my mother tried to find the chainsaw and the “expert” gave her an Eager Beaver II in a very poor condition, saying that it was beyond repair. I believe that chainsaw wasn’t my father’s chainsaw, but as there was no receipt I cannot prove anything. My mother stored it in a box and forgot about it.

Last week I found it consigned in my mother’s store room and took it to have a go with it.

I put some fresh gasoline, I pulled the rope several times, there is compression but no spark. When I researched for problems I discovered that the weak part of the chainsaws are coils that generate the spark.

The particular Eager Beaver II has a simple coil that is not working.

A search at ebay revealed that the particular coil is not available new anymore, it is hard to find and it is very expensive ($60 for a used coil).

I had to either forget all about fixing the saw or look for an alternative solution.

My first thought was to substitute it with another one from another maker. Unfortunately, every chainsaw maker designs his own coil! Some of them fit other models but none fits mine.

I noticed that coils consist of two separate parts: A laminate iron core and some windings encapsulated in a plastic container.

Most of the coils have similar containers but different laminated cores.

Solution is simple If I find a similar container I could change the core and have a brand new coil!!!!

I looked for a coil that has the same number of laminates with the original one.

It was easy to find it. Made for Husqvarna saws at a ridiculous cost (7.5$ including postage from Hong Kong!

I ordered it thinking that if it does not work I would have lost the equivalent cost of a six pack of beers!

Coil arrived and it looks promising.

I first removed the laminate core from the original part

Then, carefully, I removed the core from the new coil

A comparison of the two revealed that although they have the same number of laminates (i.e. the same thickness) they have minor differences to other dimensions so I must do some modifications to fit the old one to the new container.

First the part of the laminate that goes in the center of the container from 7.5mm had to be made 7mm. An easy work for my mill.

Next the container needed to be1mm thinner for the external leg of the laminate. Another easy job for the mill

Next, as the old laminate core is 1mm shorter, the container needed to be 1mm lower for a perfect fit.

Needless to say that During all this machining there was no wiring or electronics exposed so no harm done to the electronics.

So the old laminate iron core fits perfectly to the new coil

And there is my new part according to original specs (in comparison to the original)

It fits perfectly on the motor.

And, most important! it gives spark when I rotate the engine.

It remains to fix the carburetor and Its done!!!

Thanks for reading

Petros