Hi,

I occasionally work on or make a new stock from raw wood or blanks,

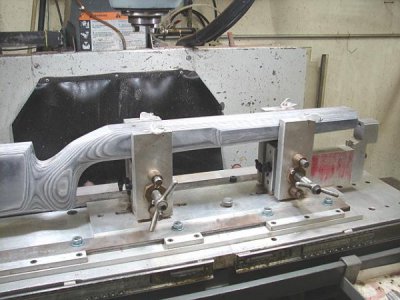

and I have a few jigs I use routers to remove most stock.

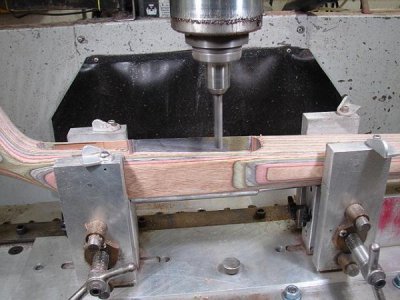

In a most cases I have used my mill for finish passes and things I need to keep accurate.

My question is, have any of you found tooling (bits) that will mill wood/synthetics reasonable at mill speeds as oposed to router speeds? (2k vs 20k)

I would like to use my small mill more often for this task but not sure what tooling I might be successful with and don't want to spend a bunch of $$$$ in the trial and error game if possible..

For reference, up to now I would make a jig, route (using a wood router), chisel close to done, then on certain operations where I need tolerance, put on mill, ( again in a jig/fixture) - then clean-up and bring to spec, etc. but wow what a process.

what tooling have you used that works decently at lower RPM where more of the process could be done in mill? (yes I have considered a router spindle build)

I'd like to pop a rough stock into the the "vise" (fixture) and hog out the majority of the in-letting and so forth (manually not CNC)

Anyway, your input greatly appreciated.

I occasionally work on or make a new stock from raw wood or blanks,

and I have a few jigs I use routers to remove most stock.

In a most cases I have used my mill for finish passes and things I need to keep accurate.

My question is, have any of you found tooling (bits) that will mill wood/synthetics reasonable at mill speeds as oposed to router speeds? (2k vs 20k)

I would like to use my small mill more often for this task but not sure what tooling I might be successful with and don't want to spend a bunch of $$$$ in the trial and error game if possible..

For reference, up to now I would make a jig, route (using a wood router), chisel close to done, then on certain operations where I need tolerance, put on mill, ( again in a jig/fixture) - then clean-up and bring to spec, etc. but wow what a process.

what tooling have you used that works decently at lower RPM where more of the process could be done in mill? (yes I have considered a router spindle build)

I'd like to pop a rough stock into the the "vise" (fixture) and hog out the majority of the in-letting and so forth (manually not CNC)

Anyway, your input greatly appreciated.