I believe i am on the slowest rpm on the watchmaker’s i didnt want to go to fast. I could bump it up i guess. I have diamond sticks to hone the brazed carbide. I found a decent looking one that i could use with a little honing. For how small the part is i could maybe go one belt notch faster. After that i will just go to the big lathe and go with carbide.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Models for grinding HSS Lathe Tools

- Thread starter mikey

- Start date

I saw your other thread, I didn't realize how small the part is. Yeah, you can probably speed it up some.

I would keep the radius small, but it might help make it easier to get the radius in the shoulder if you use something close to the radius you want in the part. Increasing the radius also increases the tool pressure, but you do get a better finish unless you cause chatter. If you do have chatter, you might want to remove most of the material with a very sharp tool with minimal radius, then switch to a larger radius tool to make a finish pass. Unless you're getting into form tool territory, I doubt it will be much of a problem though.

I would keep the radius small, but it might help make it easier to get the radius in the shoulder if you use something close to the radius you want in the part. Increasing the radius also increases the tool pressure, but you do get a better finish unless you cause chatter. If you do have chatter, you might want to remove most of the material with a very sharp tool with minimal radius, then switch to a larger radius tool to make a finish pass. Unless you're getting into form tool territory, I doubt it will be much of a problem though.

- Joined

- May 10, 2017

- Messages

- 1,199

Yeah, there are probably 20 or more sets floating around out there. Honestly, finding a set to be forwarded to you would involve much more effort than just making a set and dropping them in the mail to you. I’d have to sort through pages of PM’s to figure out who has a set to forward you.So, are there still a few of the sample sets floating around? After a couple of months of stalking Facebook Marketplace, I finally scored one of the coveted(?) 1/2hp Craftsman Belt Sanders. I'm working up my material list for the rest and will order materials on Monday. I'm guessing it'll be a month or so before I have the modifications done due to a scheduled vacation, but would love to get busy sharpening as soon as it's complete.

I've also recently purchased a Logan / Wards 10" lathe. It needs a good cleaning and a new belt, but should be good to go around the same time. I'm looking forward to this as I've been using a cheap HF 7x10 with lots of issues...

Attached is the general and very rough plan for the new rest, taken straight from that excellent article by @mikey .

‘Drop me a PM with contact info and I’ll make a set in the next day or so and get them to you.

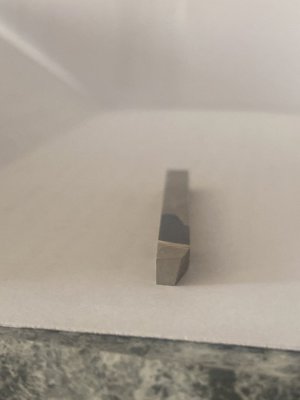

‘Remember, these will be made of cheap key stock. NOT WORKING TOOLS, they are just models for you to work to.

‘Glade to do it, just get me your contact info

Jeff

- Joined

- Oct 7, 2020

- Messages

- 2,115

Would you be into making two sets? Or maybe @Cavediver would send them to me when he gets a handle on grinding his own.

Tim

Tim