- Joined

- Oct 29, 2012

- Messages

- 1,328

I didn't get a chance to tinker with the compressor this evening but I opened up the yaskawa files I was working with back then and I see why I did what I did. V1000 doesn't have torque mode so I basically had to roll my own. V1000 is the entry level Yaskawa; higher models do have torque mode. And of course GS2 doesn't have it because that's an even more dumbed down drive than V1000. Other high end drives also have torque mode (officially "torque control" mode) - Toshiba AS3 (ref manual E6582106), Parker 690+, 890 drives, AC30, AC10, Some Lenze drives I believe, and some SEW (Movitrac I think?) drives I have seen running torque control applications.There is no ''Torque Mode'' parameter in VFDs that I'm aware of. I think the problem you were seeing with your compressor is due to the firmware in the VFD. It is not programmed to foldback and sacrifice speed to maintain constant power supplied to the motor. Quite the contrary, it is programmed to keep increasing the output power and maintain constant speed, which it will do until it faults out due to over current. You implemented the only way I know of to maintain constant power output, and that is to use an external controller. I was going to do the same thing with my compressor and realized I would need a computer in the mix to make it all work. I have never implemented that.

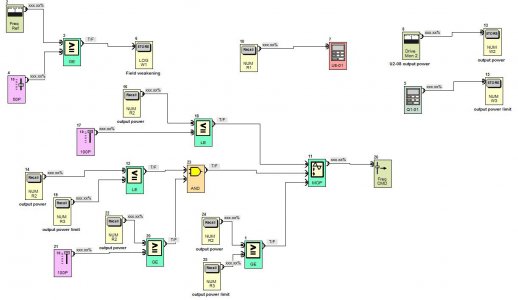

Anyway, I've attached a snapshot of my constant HP program from the onboard Yaskawa onboard PLC in case you ever rekindle the idea of the constant HP compressor. You could probably do this in AD/Delta GS4/GS20 onboard PLC.