- Joined

- Feb 9, 2017

- Messages

- 5,252

Uh, you got the wrong lathe there mate, 9x20 uses grease in the spindle bearings and there are no external grease points.don't forget the top off the head stock there is are 2 oilers for the main spindle bearings.

Uh, you got the wrong lathe there mate, 9x20 uses grease in the spindle bearings and there are no external grease points.don't forget the top off the head stock there is are 2 oilers for the main spindle bearings.

The Grizzly G4000 has (or had) 2 oilers for the spindle bearings. Enco and maybe other iterations of the same 9x20 do not, and have greased / inaccessible bearings with no external lube points.Uh, you got the wrong lathe there mate, 9x20 uses grease in the spindle bearings and there are no external grease points.

These ER collets are great for small work. I have an ER32 for my mini-lathe, and an ER40 for my G0602 10x22. The ER32 collets are way cheaper than the ER40's in my experience. It's great to be able to flip parts over without worrying about maintaining concentricity. I've had very good luck with the TIR on my sets.I am only fooling myself saying that I will get rid of this lathe since I have the other two...

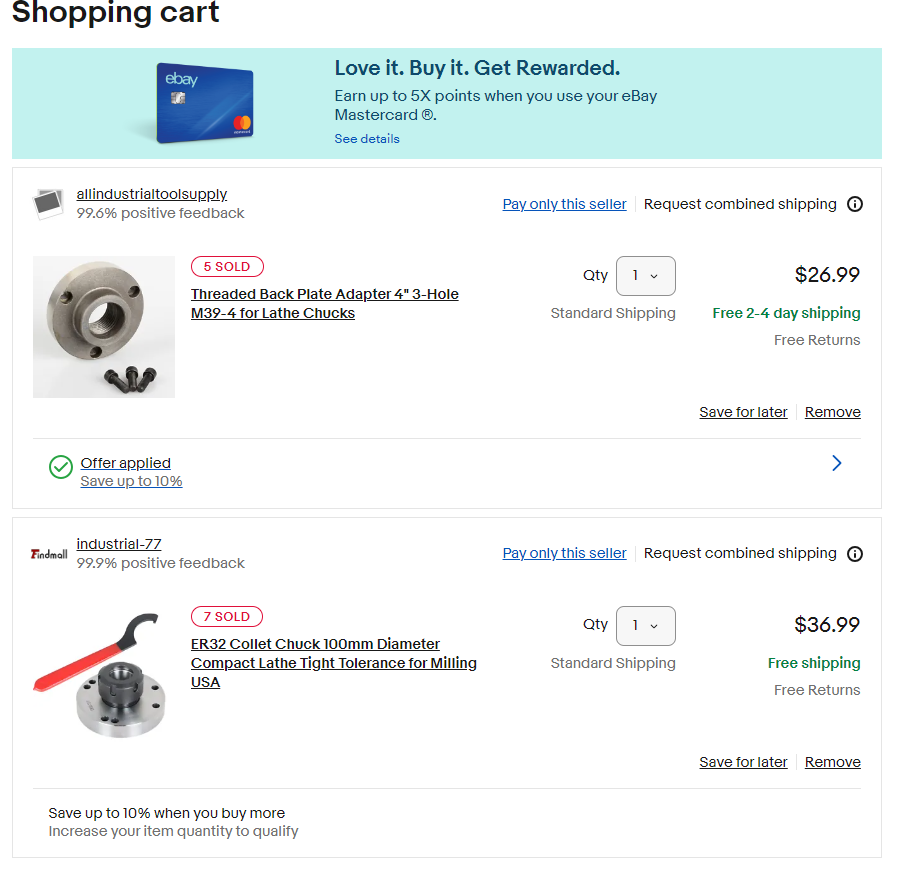

So figured I would get an ER32 setup for it... Order placed

I have ER40 on the larger lathe. ER32 in the Logan and, soon, also on this 9x20.I also went ER40 a while back and it is super handy, especially for turning balls because it doesn’t have the jaws etc sticking out.

I also went ER40 a while back and it is super handy, especially for turning balls because it doesn’t have the jaws etc sticking out.

I’m in the same “hindsight is 20/20” dilemma often too. I’m never sure if it’s based on some little faulty piece of info I picked up somewhere or just inexperience. I do get blinders and get going in the wrong direction. With the ER40 I went that way because the ER32 didn’t go big enough for what I needed to do. So it was a leap of faith was all.Backplate and ER chuck arrived.... Now I am scratching my head as to why in the world I did not go with ER40 across the board on all three lathes!!??

I am still looking at it… and I have eBay opened…I’m in the same “hindsight is 20/20” dilemma often too. I’m never sure if it’s based on some little faulty piece of info I picked up somewhere or just inexperience. I do get blinders and get going in the wrong direction. With the ER40 I went that way because the ER32 didn’t go big enough for what I needed to do. So it was a leap of faith was all.