lets see - some catch up!

2 VFDs hooked up, controls built (added a slow/rapid to the power feed using the VFD), everything rewired.

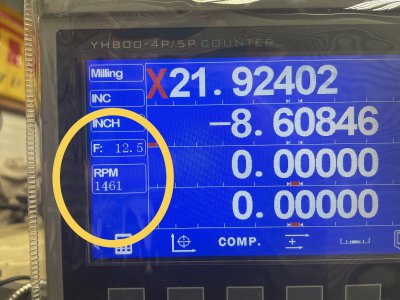

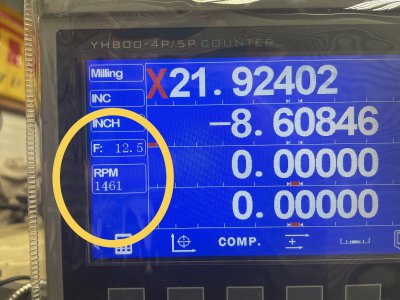

tach sensor for the control box and for the DRO installed - sadly the one on the controls doesnt work, worked fine testing it unmounted, so it might be the VFD interfering? I dunno. happily the DRO tach works perfect.

x/y/z scales mounted for the DRO. the Z was particularly painful because there's nothing flat on the side of this machine. ended up taking a page from Ted on the Induma facebook group and mounting it to a piece of steel stock with 4 leveling bolts, indicating that in, then tweaking the scale.

I still have a quill scale to add at some point, but that's going to be a lot more work.

adjusted gibs.

power feed clutched out very easy (even with the gibs loose or even removed...), which lead down into that rabbit hole of previously damaged parts. picked up a bridgeport version of the clutch, which grabs _too_ much, tried and failed to cut a new key slot in the hardened shaft (for the clutch) because the old one will not come out and is sheared and lets the new clutch spin. all I can do is break and burn endmills on this (even a center drill will make a oil puddle then goes flat), so my milling experience is not leveling up.