I am doing a bit of clock work again, as well as attempting work on vintage pocket and wristwatches, and have reconstituted my horological workstation. I am not really steady of hand, and had given up trying to work on watches, but now realize my workstation wasn’t set up to allow me to relax. So I’m trying again.

With clocks, the project of the moment is modifying a Hans Winterhalder movement from the 1920’s to fit in a slightly older Furtwängler tall case. (The case came to me without movement.) These modifications require shortening and rearranging the chiming and striking mechanisms on the back of the movement. So, I need to be able to cut and pivot some steel shafts.

Yes, I now own a South Bend lathe. But it’s kinda hard to chuck up a 1mm blued steel rod in that puppy.

Now, it’s true that my Peerless watchmaker lathe is a bit small for clock work. But I already have it—I just needed to get it set up.

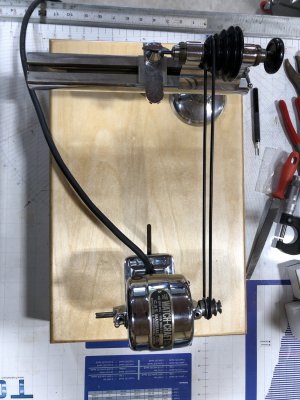

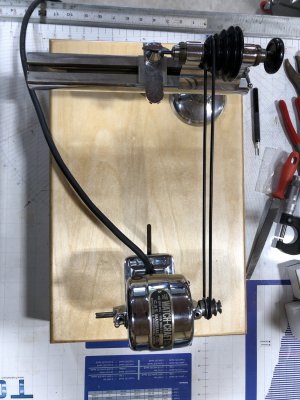

I built a new base for it with a furniture-grade plywood top and hard maple sides, which works perfectly. And I rewired the motor and foot pedal to prevent electrocuting myself or burning dow the shop. I think this one is from the 1950-ish period.

Here is is:

I left room for an intermediate transmission, but I’ve never needed it before.

TIR of chucked-up 4mm blued steel wire is about two tenths.

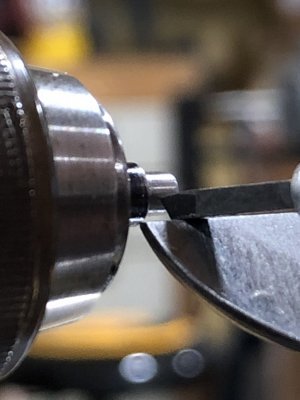

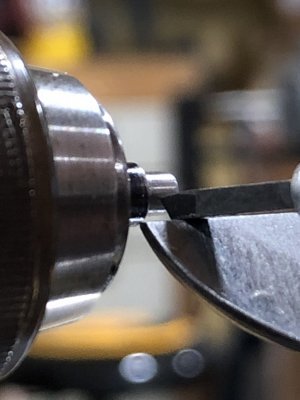

I tested it using a Waller carbide graver, freshly honed, turning the end of that 4mm hardened steel down to a 2.5mm pivot.

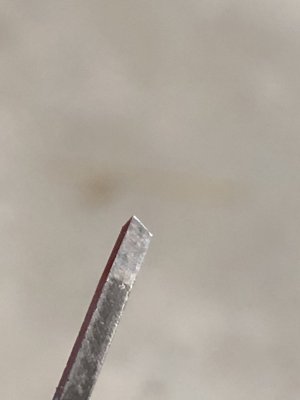

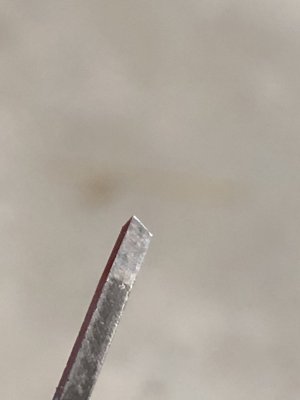

I dress the gravers using a Waller diamond-paste lapping kit, after roughing on the 600 and 1200-grit diamond hones in my knife-sharpening kit. But they rarely need more than a touch-up.

I also had to dress up the tool rest, for which I used sharpening stones.

Anyway, these lathes are supposedly too small for clocks but I rarely need to turn anything bigger than 4mm.

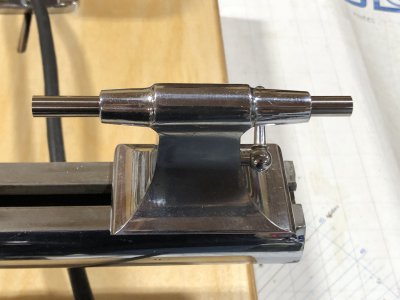

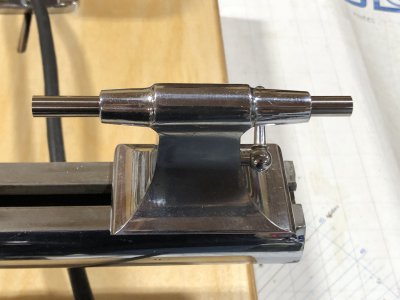

The tailstock needs a dead center, which has gone missing. I have a piece of .297 hardened reamer blank, and another at .303. The tailstock takes .300, so I need to emery down the .303 rod to fit with no play, and then attempt to turn a center on it. I’ll do that in the South Bend in the fullness of time. Here it is with the .297 rod, but that one wobbles by a few thou and that’s too loose—the tightener works but a center won’t be repeatable.

Final note—I bought a cheap Chinese 4mm Jacobs-style chuck that mounts in a WW 8mm collet spindle, and TIR on that is about half a thousandth. That’s pretty good given that turning is done manually using gravers, and given that clocks don’t require the precision of watches. I also have an ER-11 set for it, as yet untested.

Rick “for your Peerless pleasure” Denney

With clocks, the project of the moment is modifying a Hans Winterhalder movement from the 1920’s to fit in a slightly older Furtwängler tall case. (The case came to me without movement.) These modifications require shortening and rearranging the chiming and striking mechanisms on the back of the movement. So, I need to be able to cut and pivot some steel shafts.

Yes, I now own a South Bend lathe. But it’s kinda hard to chuck up a 1mm blued steel rod in that puppy.

Now, it’s true that my Peerless watchmaker lathe is a bit small for clock work. But I already have it—I just needed to get it set up.

I built a new base for it with a furniture-grade plywood top and hard maple sides, which works perfectly. And I rewired the motor and foot pedal to prevent electrocuting myself or burning dow the shop. I think this one is from the 1950-ish period.

Here is is:

I left room for an intermediate transmission, but I’ve never needed it before.

TIR of chucked-up 4mm blued steel wire is about two tenths.

I tested it using a Waller carbide graver, freshly honed, turning the end of that 4mm hardened steel down to a 2.5mm pivot.

I dress the gravers using a Waller diamond-paste lapping kit, after roughing on the 600 and 1200-grit diamond hones in my knife-sharpening kit. But they rarely need more than a touch-up.

I also had to dress up the tool rest, for which I used sharpening stones.

Anyway, these lathes are supposedly too small for clocks but I rarely need to turn anything bigger than 4mm.

The tailstock needs a dead center, which has gone missing. I have a piece of .297 hardened reamer blank, and another at .303. The tailstock takes .300, so I need to emery down the .303 rod to fit with no play, and then attempt to turn a center on it. I’ll do that in the South Bend in the fullness of time. Here it is with the .297 rod, but that one wobbles by a few thou and that’s too loose—the tightener works but a center won’t be repeatable.

Final note—I bought a cheap Chinese 4mm Jacobs-style chuck that mounts in a WW 8mm collet spindle, and TIR on that is about half a thousandth. That’s pretty good given that turning is done manually using gravers, and given that clocks don’t require the precision of watches. I also have an ER-11 set for it, as yet untested.

Rick “for your Peerless pleasure” Denney

Last edited: