- Joined

- Oct 7, 2020

- Messages

- 2,127

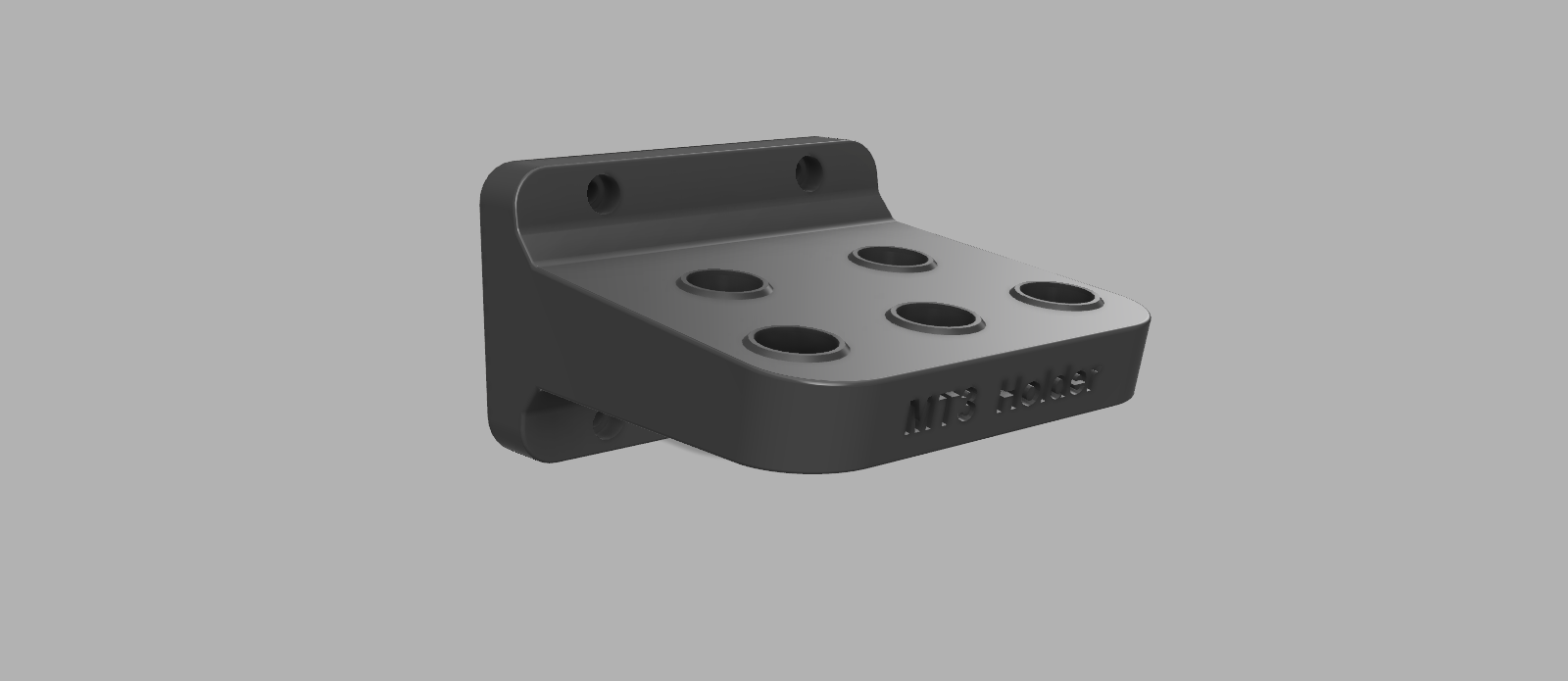

So, what is the best way to print this part? Mounting surface down, top face or on the bottom face? I'm thinking the bottom down with supports just like the photo. There is a good chance of having 5 to 6 lbs. of weight hanging on it.

Should I print it with a layer height of 1.5mm or .20mm?

Option 1: If I print it with PLA set at .20mm layer and Quality setting, 15% infill with supports on the build plate only it is going to take 1 day, 6 hours and 11 minutes.

Option 2: If I print it with PLA set at .20mm layer and Speed setting, 20% infill with supports on the build plate only it is going to take 23 hours and 57 minutes.

Option 3: If I print it with PLA set at .15mm layer and Speed setting, 20% infill with supports on the build plate only it is going to take 1 day, 4 hours and 33 minutes.

Option 4: If I print it with PLA set at .15mm layer and Quality setting, 15% infill with supports on the build plate only it is going to take 1 day, 12 hours and 31 minutes. Holy cow that is a long time.

Now if I print it on the mounting surface down.

Option 5: PLA set at .20mm layer and Quality setting, 15% infill no supports it is going to take 22 hours and 15 minutes.

Lots of options isn't there? Maybe I should redesign the part and hollo out the underside, maybe that will help. No big deal either way I just want it to hold my drill chucks without braking.

Just looking for some input on the best way.

Should I print it with a layer height of 1.5mm or .20mm?

Option 1: If I print it with PLA set at .20mm layer and Quality setting, 15% infill with supports on the build plate only it is going to take 1 day, 6 hours and 11 minutes.

Option 2: If I print it with PLA set at .20mm layer and Speed setting, 20% infill with supports on the build plate only it is going to take 23 hours and 57 minutes.

Option 3: If I print it with PLA set at .15mm layer and Speed setting, 20% infill with supports on the build plate only it is going to take 1 day, 4 hours and 33 minutes.

Option 4: If I print it with PLA set at .15mm layer and Quality setting, 15% infill with supports on the build plate only it is going to take 1 day, 12 hours and 31 minutes. Holy cow that is a long time.

Now if I print it on the mounting surface down.

Option 5: PLA set at .20mm layer and Quality setting, 15% infill no supports it is going to take 22 hours and 15 minutes.

Lots of options isn't there? Maybe I should redesign the part and hollo out the underside, maybe that will help. No big deal either way I just want it to hold my drill chucks without braking.

Just looking for some input on the best way.