Ok, I've called and spoken to several places that sell drives over the past year. I've purchased 2 VFD's myself. One for a State Mfg. Spindle sander (1HP - 3PH) and my Wells Index (2HP - 3PH). While there can be a lot of factors to consider, motors and loads like these mills are fairly straight forward. The basics of sizing a VFD is to look for the amp rating on your motor. Most newer motors these days will have an FLA value (full load amps) but in your case (and mine too) it's the Amp rating. In your case, this motor will pull 3.8 Amps at 220 Volts. From there, you want to look for a VFD that can take the input voltage you are able to provide in your shop, either single phase 110V or single phase 220V AND that will output, in your case, 220V 3 phase power. I'm assuming you can provide a 220 single phase line to your mill but let me know if you have questions. Next is to look at the FLA value of the VFD and pick one whose FLA rating is no more than about 30% higher than your motor rating. You'll want to stay within that 30% range to avoid needing an additional over voltage protection component (for safety)

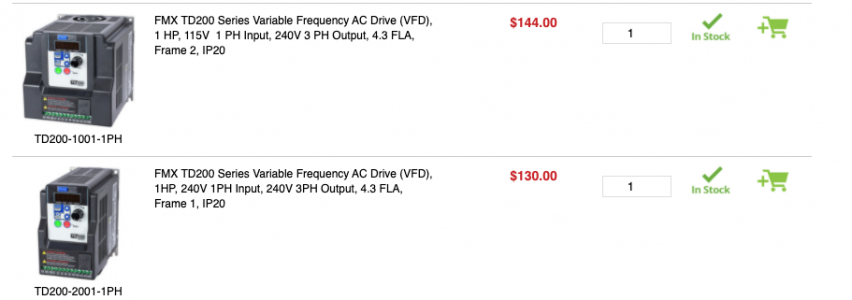

I bought my VFD from factorymation so i'll just show you an equivalent one to what I purchased since I have actual hands on experience with them. The FMX TD200 line are their straight forward VFD that can handle most 3 PH motor requirements up to 3HP. When you look at the list

here you can quickly browse down the list to find one that matches your specs. The TD200-2001-1PH would match your motor nicely. It's FLA value of 4.3 is above your motors 3.8 requirement and not greater than 30% higher.

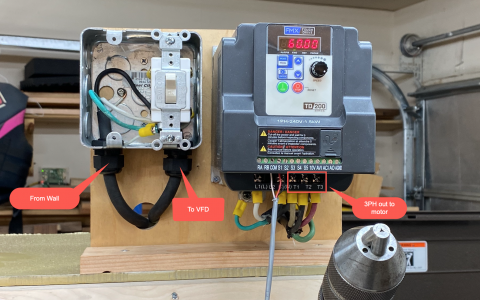

Wiring is actually really straight forward. The VFD has clearly marked slots where your incoming lines go as well as the 3PH lines out to the motor. Once you get it all wired up, there are some basic steps you would follow to configure the VFD to tell it the size of the motor it is etc... Those steps are located in their quick started guide

here. The most important initial setting is to tell the VFD the motor fla value. From there, it's a breeze.

The VFDs themselves are really very versatile. You can get them with more buttons on the faceplate such as a dedicated forward/rev button which you may actually want to consider however, if your have some basic electronics understanding you can add an external 3 position switch to control the fwd/stop/rev behaviors. You'll want to read up or watch a couple of vids of VFDs in use on Youtube.

For comparison, here's a

TD400 series vfd that has a dedicated fwd/rev button on the face.

Please let me know if you have any questions.