Harig Lubrication System

As I mentioned the original lube pump was missing and was replaced with a hand one shot oiler mounted on the side of the column. It was plumbed just as the original electric pump was and did provide oil to the column and ways, that is as long as you remembered to actually use it. However, I thought it best to go back to an automatic pump with a filter.

The original system is what I would call a "pump assisted gravity oiling system", not unlike a car engine. The pump sits in a sump at the rear of the machine and pumps filtered oil to the top of the column where it lubricates the down feed bevel gears and the thrust bearing. There is an oil site glass at the top of the column so you can verify oil is getting up there. Oil then runs down the lead screw lubricating the threads in the spindle housing and is then directed to the four vertical ways where it runs back down to the sump. Oil is also pumped to the saddle where is lubricates the table ways and then flows down to lubricate the base ways and returns to the sump and is recirculated. Here is a diagram of the system from a Harig sales brochure.

![IMG_1868[1].JPG IMG_1868[1].JPG](http://www.hobby-machinist.com/attachments/img_1868-1-jpg.467940/)

I found two oiling problems with the machine. There is supposed to be an oil cup with a lid on the rear of the machine for checking and adding oil, but it was missing. There is also supposed to be another oil cup, without a lid, sitting under the vertical column ways to catch oil and channel it thru a cavity in the base to the cross-feed nut. Oil would be wicked up to the nut via a piece of felt material. It appears that a previous owner moved the oil cup with the lid to the position under the ways thus preventing it from catching oil and likely led to the excess backlash in the crossfeed screw.

The second issue had to do with the oil channels in the saddle. When the saddle was machined grooves were cut lengthwise front to back and then the corners were filled with some sort of material to create a "moat" to hold the oil. There is a hole in the rear of the moat that provides a path back to the sump. On this machine one of the corners of the moat had been broken off, thus allowing oil to leak out and run down the front of the machine. I repaired the corner with some fiberglass filler. This is why it is important to level the machine as these moats are not very deep and oil will easily leak out if the machine is not level.

![IMG_1869[1].JPG IMG_1869[1].JPG](http://www.hobby-machinist.com/attachments/img_1869-1-jpg.467953/)

![IMG_1681[1].JPG IMG_1681[1].JPG](http://www.hobby-machinist.com/attachments/img_1681-1-jpg.467951/)

A replacement pump for the this machine is $950, which is way too much for hobby machinist budget. So, I did some research and decided on an inexpensive submersible pump for aquarium's, etc., I found on Amazon for less than $14. It is rated on 330 GPH and 25Watts and is small enough to fit in the sump. I was concerned that it would not be able to pump oil as well as water so I did some preliminary testing using transmission fluid instead of oil as it is thinner, and it worked fine.

![IMG_1844[1].JPG IMG_1844[1].JPG](http://www.hobby-machinist.com/attachments/img_1844-1-jpg.467954/)

![IMG_1653[1].JPG IMG_1653[1].JPG](http://www.hobby-machinist.com/attachments/img_1653-1-jpg.467955/)

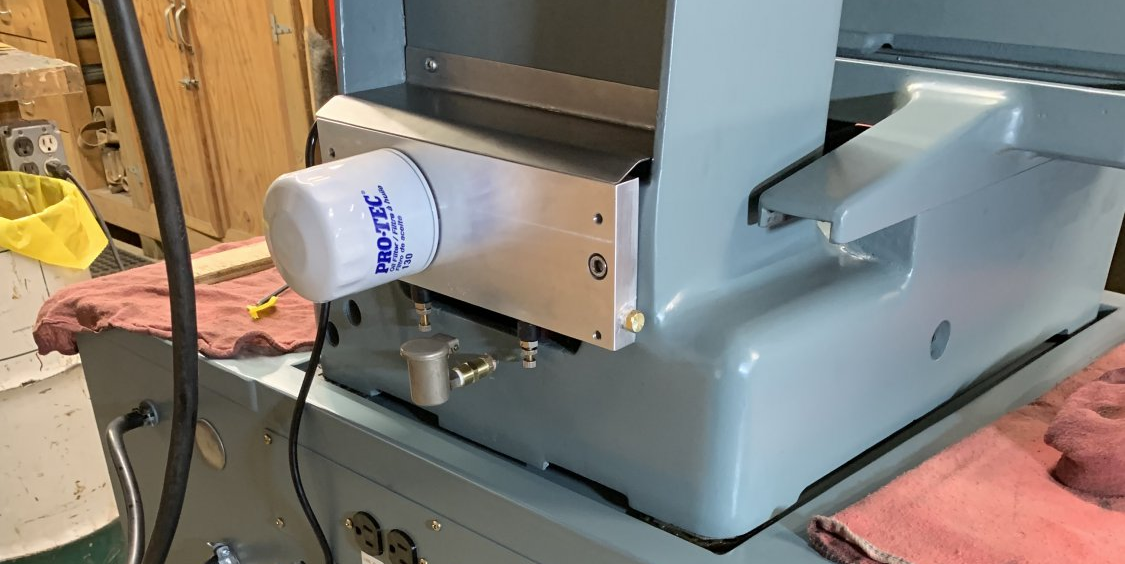

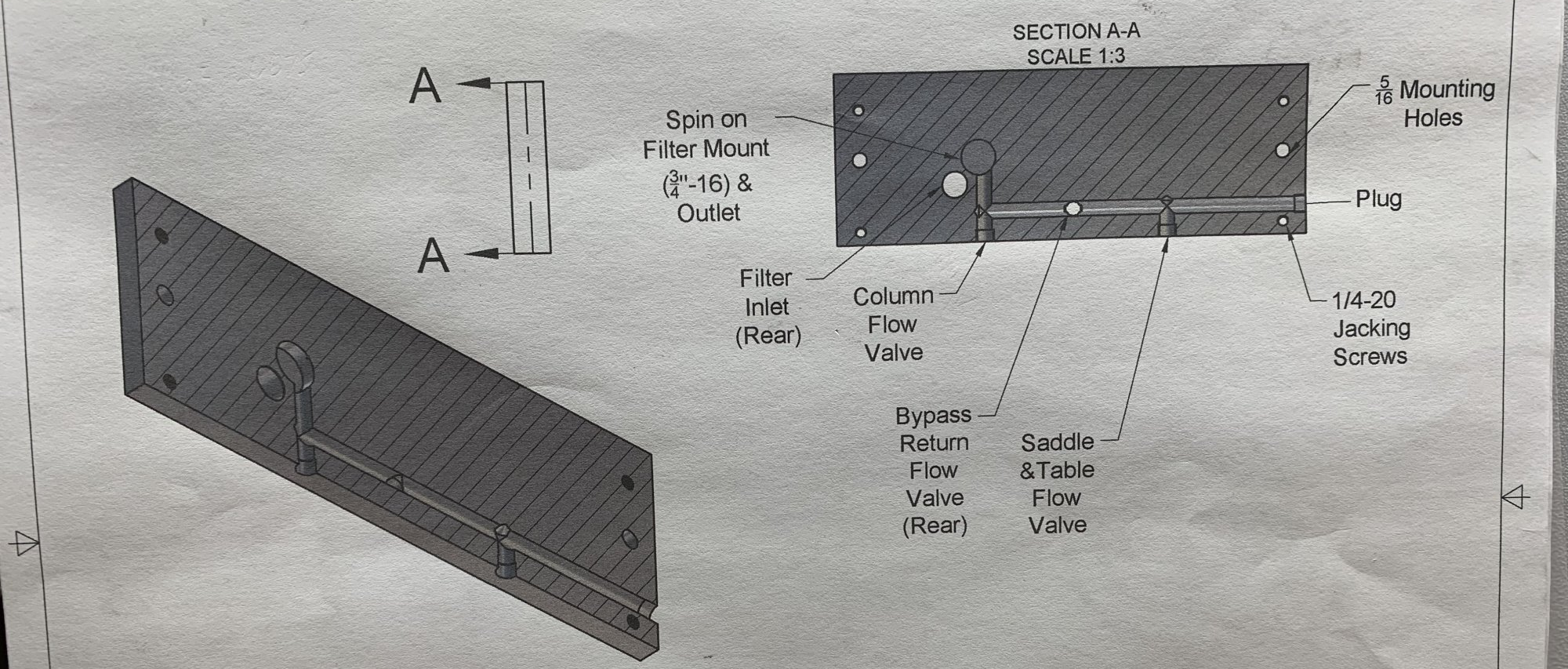

The next thing I tackled was a filter. After looking at different options I decided a small automotive type filter that I could mount on the back of the machine making it easier to replace. So, I designed and machined a piece of aluminum flat bar (3/4" x 3-1/2" x 12") to work as an oil manifold and filter mount. It bolts to the back of the machine and has 4 jacking screws to help support it to the uneven casting. And of course a new cover to help keep stuff from falling into the sump.

Oil enters the filter on its outer perimeter, so the pump output connects straight through the manifold into the filter. Oil leaves the filter through the center hole and is channeled to the two adjustable valves you see at the bottom. (these valves are sold as air valves but work fine with oil). One goes the top of the column, the other to the saddle. There is a 3rd output from the manifold that allows oil to go directly back into the sump as a sort of bypass to help regulate the amount of oil going to machine. It turns out the bypass valve needs to be almost completely closed to allow enough flow to the machine. It's likely the filter is putting some restriction on the flow from the small pump.

I decided to stay with transmission fluid as the lubricant. It's inexpensive (did I mention I'm cheap), it is thinner than oil, and for the infrequent use of a hobby machine it provides adequate lubrication. So far it is working fine, all movements are very smooth.

![IMG_1806[1].JPG IMG_1806[1].JPG](http://www.hobby-machinist.com/attachments/img_1806-1-jpg.467965/)

![IMG_1807[1].JPG IMG_1807[1].JPG](http://www.hobby-machinist.com/attachments/img_1807-1-jpg.467966/)

I did modify how the crossfeed is lubricated. To lubricate the saddle oil is pump thru a cavity in the base and comes up under the saddle and is plumbed to the saddle via a hose. I tapped into this path and feed an adjustable valve feeding the crossfeed nut. There is a drain in the bottom of the new nut that uses the cavity that originally feed the nut and is now a return to the sump. It works very well.

![IMG_1792[1].JPG IMG_1792[1].JPG](http://www.hobby-machinist.com/attachments/img_1792-1-jpg.467968/)

![IMG_1793[1].JPG IMG_1793[1].JPG](http://www.hobby-machinist.com/attachments/img_1793-1-jpg.467969/)

In the picture above the line at the left will connect to the bottom of saddle but I'm running back into the sump as I adjusted the valve on the new crossfeed nut.

![IMG_1745[1].JPG IMG_1745[1].JPG](http://www.hobby-machinist.com/attachments/img_1745-1-jpg.467970/)

![IMG_1659[1].JPG IMG_1659[1].JPG](http://www.hobby-machinist.com/attachments/img_1659-1-jpg.467971/)

Whew, that took longer than I thought to document. But it is an important function that will help prolong the life of this machine. I hope others will benefit from seeing this.

Jim

As I mentioned the original lube pump was missing and was replaced with a hand one shot oiler mounted on the side of the column. It was plumbed just as the original electric pump was and did provide oil to the column and ways, that is as long as you remembered to actually use it. However, I thought it best to go back to an automatic pump with a filter.

The original system is what I would call a "pump assisted gravity oiling system", not unlike a car engine. The pump sits in a sump at the rear of the machine and pumps filtered oil to the top of the column where it lubricates the down feed bevel gears and the thrust bearing. There is an oil site glass at the top of the column so you can verify oil is getting up there. Oil then runs down the lead screw lubricating the threads in the spindle housing and is then directed to the four vertical ways where it runs back down to the sump. Oil is also pumped to the saddle where is lubricates the table ways and then flows down to lubricate the base ways and returns to the sump and is recirculated. Here is a diagram of the system from a Harig sales brochure.

I found two oiling problems with the machine. There is supposed to be an oil cup with a lid on the rear of the machine for checking and adding oil, but it was missing. There is also supposed to be another oil cup, without a lid, sitting under the vertical column ways to catch oil and channel it thru a cavity in the base to the cross-feed nut. Oil would be wicked up to the nut via a piece of felt material. It appears that a previous owner moved the oil cup with the lid to the position under the ways thus preventing it from catching oil and likely led to the excess backlash in the crossfeed screw.

The second issue had to do with the oil channels in the saddle. When the saddle was machined grooves were cut lengthwise front to back and then the corners were filled with some sort of material to create a "moat" to hold the oil. There is a hole in the rear of the moat that provides a path back to the sump. On this machine one of the corners of the moat had been broken off, thus allowing oil to leak out and run down the front of the machine. I repaired the corner with some fiberglass filler. This is why it is important to level the machine as these moats are not very deep and oil will easily leak out if the machine is not level.

A replacement pump for the this machine is $950, which is way too much for hobby machinist budget. So, I did some research and decided on an inexpensive submersible pump for aquarium's, etc., I found on Amazon for less than $14. It is rated on 330 GPH and 25Watts and is small enough to fit in the sump. I was concerned that it would not be able to pump oil as well as water so I did some preliminary testing using transmission fluid instead of oil as it is thinner, and it worked fine.

The next thing I tackled was a filter. After looking at different options I decided a small automotive type filter that I could mount on the back of the machine making it easier to replace. So, I designed and machined a piece of aluminum flat bar (3/4" x 3-1/2" x 12") to work as an oil manifold and filter mount. It bolts to the back of the machine and has 4 jacking screws to help support it to the uneven casting. And of course a new cover to help keep stuff from falling into the sump.

Oil enters the filter on its outer perimeter, so the pump output connects straight through the manifold into the filter. Oil leaves the filter through the center hole and is channeled to the two adjustable valves you see at the bottom. (these valves are sold as air valves but work fine with oil). One goes the top of the column, the other to the saddle. There is a 3rd output from the manifold that allows oil to go directly back into the sump as a sort of bypass to help regulate the amount of oil going to machine. It turns out the bypass valve needs to be almost completely closed to allow enough flow to the machine. It's likely the filter is putting some restriction on the flow from the small pump.

I decided to stay with transmission fluid as the lubricant. It's inexpensive (did I mention I'm cheap), it is thinner than oil, and for the infrequent use of a hobby machine it provides adequate lubrication. So far it is working fine, all movements are very smooth.

I did modify how the crossfeed is lubricated. To lubricate the saddle oil is pump thru a cavity in the base and comes up under the saddle and is plumbed to the saddle via a hose. I tapped into this path and feed an adjustable valve feeding the crossfeed nut. There is a drain in the bottom of the new nut that uses the cavity that originally feed the nut and is now a return to the sump. It works very well.

In the picture above the line at the left will connect to the bottom of saddle but I'm running back into the sump as I adjusted the valve on the new crossfeed nut.

Whew, that took longer than I thought to document. But it is an important function that will help prolong the life of this machine. I hope others will benefit from seeing this.

Jim

![IMG_1870[1].JPG](/data/attachments/425/425196-94517168f3000b7c66b3f18d03c0aca8.jpg)

![IMG_1842[1].JPG](/data/attachments/425/425189-2fc3332818b1b4e910bb270248c66d70.jpg)

![IMG_1843[1].JPG](/data/attachments/425/425190-ac0e62effabe286cc4e88466f1def4f2.jpg)

![IMG_1843[1].JPG](/data/attachments/425/425825-ac0e62effabe286cc4e88466f1def4f2.jpg)

![IMG_1879[1].JPG](/data/attachments/425/425823-ab06189a7743820f6d2b5efa9389b610.jpg)

![IMG_1827[1].JPG](/data/attachments/427/427032-121ee867bea925bbe53a1800583a5bfd.jpg)

![IMG_1822[1].JPG](/data/attachments/427/427029-d589654cfefb304e1c207b64eda0ab2f.jpg)

![IMG_1824[1].JPG](/data/attachments/427/427028-f4f5b80ada34b19db52c5fabdea6297d.jpg)