- Joined

- Sep 27, 2014

- Messages

- 3,123

found a guy selling a bunch of nos,nib SB lathe assessories mostley 10k , 9" stuff ,

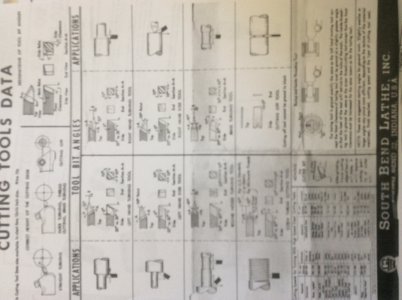

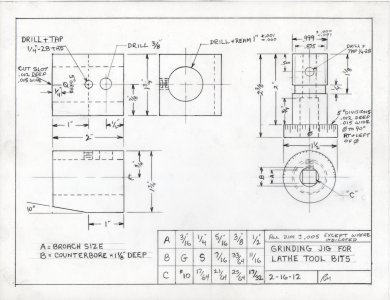

I'm going to look at the SB tool sharpening jig , comes with four different size tool holders 1/4 - 1/2 " and the block that holds them

He wants 125.00 for it is new in box never used. He said he has lots of nos SB stuff not listed yet.

I'ed mention where they are but don't want to get in trouble again, well mabey after I see what he has I'll , o yea the classified section is broke , and no more expressions ,I'll see what he has

Derrick

I'm going to look at the SB tool sharpening jig , comes with four different size tool holders 1/4 - 1/2 " and the block that holds them

He wants 125.00 for it is new in box never used. He said he has lots of nos SB stuff not listed yet.

I'ed mention where they are but don't want to get in trouble again, well mabey after I see what he has I'll , o yea the classified section is broke , and no more expressions ,I'll see what he has

Derrick