- Joined

- Mar 1, 2012

- Messages

- 1,140

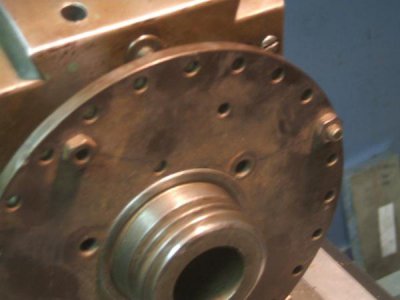

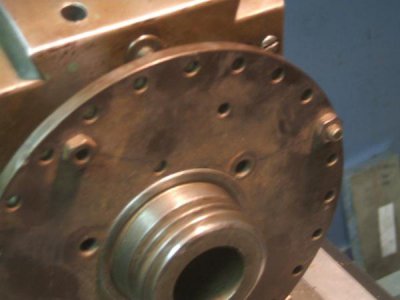

I picked up this universal dividing head last week. I torn it down and cleaned out the decades of grime that was inside it. Put it back together, adjusted the worm and spindle properly now it spins smooth as silk, with no backlash.

The quick index plate on the spindle is cracked and has been somewhat repaired in the past. I'm going to try brazing the cracks and see how it looks. If it doesn't work out I'll make a new one.

It originally had little pop up oilers, two were missing and I damaged the other one knocking it out. So I'm going make new ones.

I need to find a couple of acessories for it.

Tailstock

#10 Brown & Sharpe dead center

Chuck mounting plate 2 1/4"-4 1/2 threads per inch

I pretty sure I'll have to make the chuck plate because I haven seen anything in that old spindle thread size in years. But if someone has one laying around let me know.

The quick index plate on the spindle is cracked and has been somewhat repaired in the past. I'm going to try brazing the cracks and see how it looks. If it doesn't work out I'll make a new one.

It originally had little pop up oilers, two were missing and I damaged the other one knocking it out. So I'm going make new ones.

I need to find a couple of acessories for it.

Tailstock

#10 Brown & Sharpe dead center

Chuck mounting plate 2 1/4"-4 1/2 threads per inch

I pretty sure I'll have to make the chuck plate because I haven seen anything in that old spindle thread size in years. But if someone has one laying around let me know.