-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OldCarGuy's Toy Shops

- Thread starter OldCarGuy

- Start date

- Joined

- Jan 25, 2015

- Messages

- 2,558

I am jealous of all that space and I’ve got two double car garages.

I don’t have as many cars, although I wish I did.

I have to console myself with a corvette, mustang and mini cooper as project cars. No space for more as the wife demands there is space in the winter for her to park inside. Although I do have 4 motorcycle projects when I feel like some light wrenching using minimal space.

Same here with wheels, wings or hulls. They all bring me much joy, either using them or working on them. I’m one of those guys that just “gets” machines. Drop a bucket of loose parts in front of me and I’ll put whatever it is together with nothing more than a tool box. Sounds like you might be the same….

My professional career took a slightly diff path though: ticketed mechanic to university, then military aerospace engineering and ending with flying helicopter SAR…medically retired and now I just wrench at home on my own stuff to keep busy.

Vette (driver):

Mustang (roller):

Mini (wifes summer driver, just finished a full engine rebuild):

Older pic of some of the bikes (all in pieces and various stages of build up now):

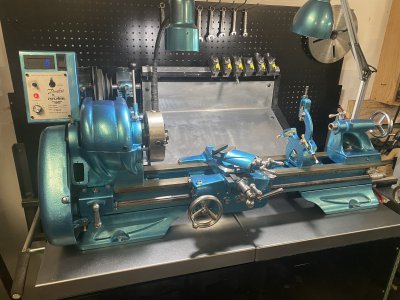

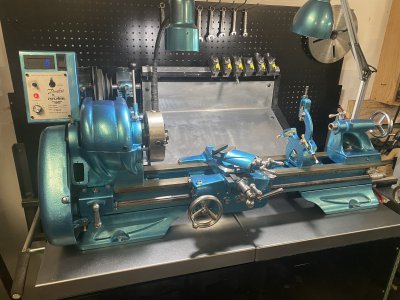

and for good measure, my recently “restored” Atlas TH42:

Always looking for a new project. I’ve actually been restoring sewing machines lately. They’re a fun little diversion for the inside winter months…

I don’t have as many cars, although I wish I did.

I have to console myself with a corvette, mustang and mini cooper as project cars. No space for more as the wife demands there is space in the winter for her to park inside. Although I do have 4 motorcycle projects when I feel like some light wrenching using minimal space.

Same here with wheels, wings or hulls. They all bring me much joy, either using them or working on them. I’m one of those guys that just “gets” machines. Drop a bucket of loose parts in front of me and I’ll put whatever it is together with nothing more than a tool box. Sounds like you might be the same….

My professional career took a slightly diff path though: ticketed mechanic to university, then military aerospace engineering and ending with flying helicopter SAR…medically retired and now I just wrench at home on my own stuff to keep busy.

Vette (driver):

Mustang (roller):

Mini (wifes summer driver, just finished a full engine rebuild):

Older pic of some of the bikes (all in pieces and various stages of build up now):

and for good measure, my recently “restored” Atlas TH42:

Always looking for a new project. I’ve actually been restoring sewing machines lately. They’re a fun little diversion for the inside winter months…

Last edited:

- Joined

- Jun 7, 2013

- Messages

- 10,142

Way too clean ---

But are you happy?

HAPPY! I'm in seventh Heaven. All of my children are living on their own. Extremely successful and have wonderful families. Today I'm having the time of my life, and living for me. Knowing that I created my toy shops with my own two hands is simply icing on the cake. I walk through my shops and smile..

Here's a project for you.Welcome to our little group.

We have a saying around here, pictures or it didn't happen.

It's surely happening at your place....

Would love to see more of your projects, you're sure to be a welcome addition here with the knowledge you have to share.

John

NEVER! But thanks for noticing. A clean working shop is far more efficient. Plus one doesn't get frustrated looking for things. Everything can be found in their place...Way too clean ---

I am jealous of all that space and I’ve got two double car garages.

I don’t have as many cars, although I wish I did.

It may be time to build more garage space.

Love the wheels, and nice job on the lathe! You must possess the same gene I was born with..

More Pictures of my machines in the mainshop:

All the input power is located on onewall. The 200 Amp main breaker 32-space Single Phase Load Center isto the right of the picture. The (3) Three-Phase Rotary PhaseConverters are fed from the main panel. Into a relay box that allowsany single and or up to three RPC to power up the 100 Amp 3-PhaseLoad center with eight 3-Phase breakers. All the 3-Phase machines arewired from that panel overhead or under the floor through conduit.There is one 5 HP GWM, one 10 HP DES-CO, and one 15 HP AmericanRotary RFC.

Radial drill press.

30 AMP Plunge EDM machine

Roll-in Saw

Bridgeport clone, three axis readouts,power draw bar

Gould & Eberhardt 16” Shaper

Kearney & Trecker Rotary Head Mill#2D

Cleveland CNC Bed-Type Vertical MillingMachine AC_35. Again Cleveland Machinery re-badged an Atrump machine.Has a Centroid full three axis controller with all software includingengraving package. Along with digital touch probe.

My collection of Gerstner Wood Machinist Tool Boxes. Two solid oak work benches. Columbian Vise

All the input power is located on onewall. The 200 Amp main breaker 32-space Single Phase Load Center isto the right of the picture. The (3) Three-Phase Rotary PhaseConverters are fed from the main panel. Into a relay box that allowsany single and or up to three RPC to power up the 100 Amp 3-PhaseLoad center with eight 3-Phase breakers. All the 3-Phase machines arewired from that panel overhead or under the floor through conduit.There is one 5 HP GWM, one 10 HP DES-CO, and one 15 HP AmericanRotary RFC.

Radial drill press.

30 AMP Plunge EDM machine

Roll-in Saw

Bridgeport clone, three axis readouts,power draw bar

Gould & Eberhardt 16” Shaper

Kearney & Trecker Rotary Head Mill#2D

Cleveland CNC Bed-Type Vertical MillingMachine AC_35. Again Cleveland Machinery re-badged an Atrump machine.Has a Centroid full three axis controller with all software includingengraving package. Along with digital touch probe.

My collection of Gerstner Wood Machinist Tool Boxes. Two solid oak work benches. Columbian Vise

Good Lord my friend. What a place!!

How do you like the Centroid controller? I am planning on converting my Trak over to Centroid this winter.

How do you like the Centroid controller? I am planning on converting my Trak over to Centroid this winter.

- Joined

- Jan 25, 2015

- Messages

- 2,558

I know a couple professional machine shops that would kill for a setup like that.

Nicely done.

Nicely done.

Last edited: